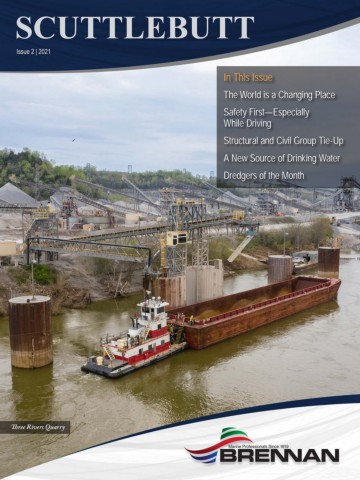

In This Issue The World is a Changing Place Safety First—Especially While Driving Structural and Civil Group Tie-Up A New Source of Drinking Water Dredgers of the Month Three Rivers Quarry

The world is a changing place THE SPEED OF THIS CHANGE IS STUNNING Since the early 1920s and extending to some point in the last decade, we have been a nation dependent upon carbon-based sources of energy. This energy was subsequently distributed through a highly inefficient “1-way” electrical power grid or at the pump at our local gas stations. During this same period, the adult working

population of this country grew, supplying more than proprietary means and methods for foundation and enough workers to support an expanding economy. tower construction of the “smart grid” infrastructure, The mobility of these people exploded when opportunities will grow in projects similar to our compared to any previous point in history, requiring recent and current work for Xcel Energy Inc. and a “built environment” for modes of transportation like American Transmission Company, LLC. And in legacy cars and airplanes. And manufacturing provided an manufacturing industries and their efforts to remediate economic base from which a strong middle class environmental liabilities, we are at the forefront of emerged. In total, in the last 100 years, we have American remedial contractors developing methods to enjoyed a familiar and long-lasting stability, with best address all manners of contamination, including smaller periods of disruption. fly ash and polyfluoroalkyl substances (PFAS). As we look forward from the 2020s, the picture Of course, one of the most daunting challenges in shifts. Energy production is changing—and quickly. front of our country is human adaptation to global Traditional carbon-based energy is giving way to climate change. As a team of people who focus on new forms that are both sustainable and more executing innovative solutions in, above, adjacent to, cost-competitive. The way we distribute power is and below water, there are few firms in the country transitioning to a “2-way smart grid” where power like ours who can provide the breadth of work use is exponentially more efficient. By 2030, our required to update aging infrastructure. population will include more retired than working adults. The “built environment” is crumbling under All of this means that now is an incredibly exciting higher levels of utilization, climate change, and age. time to grow your career here at Brennan. This is Manufacturing is changing in both what we produce the place to be for those who want to work with new and how we produce it; however, the environmental technologies, solving big problems while working legacy associated with the previous century’s with the best team. Unlike in years past, the working production requires attention. The story ahead population of this country is stagnant at best, so features “creative disruption” where industries we we must look at every avenue to help our people knew and traditional ways of doing business are no grow—our future depends upon it. Reinvestment longer sustainable. no longer is measured in new equipment, but rather in the development of people through skills-based The exciting part of this once-in-a-century moment and business-essential training to promote career is that the work Brennan does already encompasses advancement. As we grow, and we are growing, the changes we see throughout our economy. We new positions are created, and we seek to fill those are actively involved in clean energy production with positions internally with individuals who want to take our work on the many hydroelectric plants and in on the challenge and opportunity. offshore wind. We recently completed 2 projects for Ørsted Offshore North America, owner of America’s As you read this edition of the Scuttlebutt, keep in first offshore wind farm, and this work is only the mind that all the changes you see within the company beginning to further wind farm construction along the are designed to help us adapt and lead in the new East Coast. To satiate rising power needs stemming opportunities ahead. The world is a changing place. from the likes of automobile recharging, retrofits The speed of this change is stunning. We will lead in to existing power plants will also increase, similar this changing world. to our work for Florida Power & Light Company in Riviera Beach, FL. Likewise, because of our Matt Binsfeld President and Chief Executive Officer

EXPOSURE TO HEAT can cause illness and death. The most serious heat illness is heat stroke. Other heat illnesses such as heat exhaustion, heat cramps, and heat rash, should also be avoided. There are precautions that can be taken any time temperatures are high and the job involves physical work. Risk Factors for Heat Illness Symptoms of Heat Stroke Symptoms of Heat Exhaustion » High temperature and humidity, direct » May be confused, unable to think » Headache, dizziness, or fainting sun exposure, no breeze or wind clearly, pass out, collapse, or have seizures (fits) » Weakness and wet skin » Heavy physical labor » May stop sweating » Irritability or confusion » No recent exposure to hot workplaces » Low liquid intake » Thirst, nausea, or vomiting » Waterproof clothing IF THE WORKER IS NOT ALERT or seems confused, this may be a heat stroke. CALL 911 IMMEDIATELY and apply ice as soon as possible. Prevent Heat Illness When a Worker is Ill from the Heat » Establish a complete heat illness prevention program. » Call a supervisor for help. If the supervisor is not available, call 911. » Provide training about the hazards leading to heat stress and how to prevent them. » Have someone stay with the worker until help arrives. » Provide a lot of cool water to workers close to the work » Move the worker to a cooler/shaded area. area. At least 1 pint of water per hour is needed. » Remove outer clothing. » Modify work schedules and arrange frequent rest periods with water breaks in shaded or air-conditioned areas. » Fan and mist the worker with water; apply ice (ice bags or ice towels). » Gradually increase workloads and allow more frequent breaks for workers new to the heat or those that have » Provide cool drinking water, if able to drink. been away from work. This provides workers time to adapt to working in the heat (acclimatization). » Designate a responsible person to monitor conditions and protect workers who are at risk of heat stress. » Consider protective clothing that provides cooling. How to Protect Workers » Know signs/symptoms of heat illnesses; monitor yourself; use a buddy system. » Block out direct sun and other heat sources. » Drink plenty of fluids. Drink often and BEFORE you are thirsty. Drink water every 15 minutes. » Avoid beverages containing alcohol or caffeine. » Wear lightweight, light colored, loose-fitting clothes.

MONTHLY May SAFETY AWARD Jonathan WINNERS Panasik The monthly Safety Award honors individuals who go above and beyond when it comes to safety. Nominations can come from anyone in the company. All it takes to nominate someone is a short summary explaining how that person exceeded expectations regarding safety. Nominees, if demonstrated to have gone above and beyond per the summary (decided by the Safety Committee), will receive a new Brennan hoodie. If multiple nominees are submitted in 1 month, the Brennan Safety Committee votes on which individual went further out of their way to promote a better safety culture. Each monthly winner of the Safety Award gets a $25 cash gift card on top of the hoodie received by all committee-validated nominees. Submit nominations directly to Megan Lavery, Tim Butz, or Victor Buhr IV; you can also use the monthly Safety Award nomination form at jfbrennan. com/employees-safetyawards or scan this QR code with your phone’s camera: Latest Monthly Safety Award Winners March Erik Henry April Levi Schmitz

QMS as Since Brennan’s certification audit covering a Business International Organization for Standardization Differentiator (ISO) standards 9001:2015, (Quality Management) 14001:2015 (Environmental Management) and By Mike Cannell 45001:2018 (Occupational Health and Safety) in late July 2020, the company has been hard at work making our quality management system (QMS) work for us. As we continue to grow, continued standardization of process has, and will continue to, bring benefits to the services we offer to clients.

IMPORTANTLY, as we talk with existing and especially prospective clients about our road to certification under these standards we have an opportunity to discuss how those efforts justify making Brennan the service provider of choice. System of measurement—the Brennan QMS provides a system of management that is designed to be measured and monitored. We measure continuously to look for trends, periodically through internal auditing, at least annually via external audits, and as the need arises with respect to incidents and occurrences. Measuring and monitoring of our processes is comprehensive, objective, and completely transparent. Better understanding of our own problems—objective investigation of process shortcomings, identification of root causes, and proactive corrective action processes ensure that we have a thorough understanding of where we may have gotten off track and provide an objective path to true resolution of those root cause factors. Business process improvement—every process improvement we make provides the customer with a better end product, either by making it easier and more efficient to do business with Brennan or through direct improvements in client service delivery. System of continua improvement—Brennan identifies, prioritizes, and provides material support to improvement across the business. Because improvement of business processes and our management system is an integral component of the overall system, we can link areas for improvement to objective business measurements. There are many companies that do some of these things, development of our QMS has made us more flexible even reasonably well, but almost none of them are in when it comes to adapting to changes in business and in the marine construction sector. Brennan does all of dealing with client requirements. Recent experience has these things and more, and we are constantly working shown that our private clients clearly see the value that to improve these core functions because excellence in our QMS provides during the pre-qualification process these areas ensures a healthy business and facilitates and all the way through field execution of our services. rapid growth when the opportunity arises. During the next quarter, we’ll be conducting internal These are just a few of the reasons that we have chosen audits to prepare for our annual surveillance audit with to adopt an integrated quality management system but British Standards Institution (BSI), our ISO certification certainly our efforts have improved our marketability to registrar. We expect to communicate more frequently and our public and especially private client base as well. more in depth both internally and directly with our clients regarding QMS objectives, state of compliance, and the Simply put, ISO certification is a game changer for related efficiencies that we bring to the table. companies who can clear the high bar required for certification and rather than making us more rigid,

Port La Crosse By Adam Binsfeld Updates from The 2021 navigation season started in La Crosse on March 28. High Brennan demand for grain has kept the port busy in the first few months and will Marine likely continue through July. In May, the repair crews completed winter drydock work for the United States Army Corps of Engineers (USACE), including barge repairs and subchapter M improvements to the MV Butler. The Corps was very pleased with the work completed. A big thank you to Brian Goetzinger, Blake Mauss, Justin Krajewski, Sam Bernhardt, and Mike Michniak.

Three Rivers & Brickeys Brad Caulder By Karl Berthelot Karl Berthelot Andrew Topper Barge demand for aggregates at Three Rivers in Smithland, Kentucky ,and the Brickeys Quarry operation in Bloomsdale, Missouri, has not yet recovered to pre- COVID-19 levels and is down nearly 50% from this time last year. We are using the time to complete repair work on the Patriot, Constitution, and the Elizabeth Marie. The Patriot was in the shipyard for hull and tank work and then was inspected by the United States Coast Guard (USCG) and issued a Certificate of Inspection (COI). This COI made the Patriot the 9th of the 10 BMI vessels to achieve our goal of 100%. Prior to Brennan acquisition, the Patriot was a forgotten and neglected vessel. Crews have worked diligently with various members of the BMI team to bring the vessel up to our standards. Thanks to everyone’s hard work it will serve Brennan well for many years to come. The Constitution has also been in the shipyard getting hull and rudder work completed. Upon completion of this work, it will be scheduled for USCG inspection. The Merrill Colsch was in the yard in St. Louis for wheel replacements and hull work and has been issued a COI by the USCG. As the Merrill Colsch left the St. Louis yard, The Elizabeth Marie arrived, to get 2 new Mitsubishi S12 main engines and modifications for the refit; it will be docked for possible wheel replacement. With our recent inspections by both the USCG and our third-party organization (TPO), we have gotten plenty of positive feedback. It has been noted by both parties that our crews know their jobs, our programs, and were great to work with during the inspections. I want to thank everyone for being professionals and supporting the Brennan Way. Tyler Stueve New Hires Over the past quarter we have had several changes to the team with Charlie Wilkes and Dustin Payne joining at Ste. Genevieve, Tyler Stueve joining at Brickeys, and Jason Duff and Zach England joining at Three Rivers. I would like to extend a big \"Welcome Aboard\" to all of these new team members. We are expecting a busy summer at all locations and continue to look for new opportunities to help BMI grow into both our current and new markets. Thank you all for your efforts in making BMI, as I see it, the best fleeting operations on the rivers. Without your efforts and the impression you make on our customers and competitors, we would not be able to grow. You are both noticed and appreciated!!

Remember: Safety First at Brennan– Especially While Driving! By Travis Hamilton In 2021 alone, Brennan fleet vehicles have traveled 1.3 million miles. Our fleet is a moving billboard. Always be courteous of other drivers and obey all traffic laws, especially when representing Brennan and your team. Remember: Traveling at speeds 10 MPH over the posted speed limit will result in an alert to Asset Management. We also receive a notification at speeds of 85 MPH. At 85 MPH you can expect an email notifying you of your driving infraction, typically within a day or so. COMPANY POLICY HIGHLIGHTS » Business Use Only Company-owned or -leased vehicles shall not be used for any purpose other than company business or related activity, unless approved by the Chief Executive Officer (CEO) or Chief Financial Officer (CFO). » No Unauthorized Persons Employees are prohibited from transporting any unauthorized persons in company vehicles. » Observe Traffic Rules All employees driving on company business shall observe all traffic laws, regulations, and courtesies—always. Traffic fines, parking tickets, and/or penalties levied for violations of law and for which the employee is directly responsible shall be paid for by the employee.

ASSET MANAGEMENT CAN SEE DAILY REPORTS ON BRENNAN VEHICLES, SHOWING Vehicles Driven Speeding Location After Acceptable Alerts Work Hours Fault Code Low Battery & Idle Alerts Check Engine Time Codes VEHICLE MAINTENANCE REQUIREMENTS CONTACT US Employees using a company vehicle are responsible Travis Hamilton Paul Berendes for seeing that the vehicle receives preventative maintenance and has its oil changed every 5,000 MI Fleet Vehicle Coordinator Director of Asset Management to coincide with the manufacturer’s recommendations. office: 608.519.5327 office: 608.519.5336 Employees can either arrange maintenance on said cell: 608.799.3671 cell: 608.386.8659 vehicle themselves, or arrange it with Travis Hamilton. [email protected] [email protected] An employee may be held liable for damage to a company vehicle if their failure to maintain the vehicle is obviously negligent and could have easily been prevented. An employee who has an assigned company vehicle is required to keep their vehicle clean, washed, and serviced on a regular basis. Any problems with respect to an assigned vehicle must be reported to the employee’s supervisor as soon as possible. If maintenance is done on a Brennan vehicle, please send invoices to Travis Hamilton so the Asset Management group can record and track what has been done to each vehicle. If you need something for your vehicle, please contact Travis Hamilton and/or Paul Berendes for approval. REPORTING ACCIDENTS AND INCIDENTS 6. Gather as much information as you can from all parties involved in the accident. 1. Call 911 to report the incident to authorities. A police report may be necessary for some This information may include name; license number; insurance claims. insurance company; plate number; make, model, and year of vehicle; how accident the happened; 2. Report the accident immediately to Brennan and witnesses. Safety personnel and Travis Hamilton. 7. Refer all questions from lawyers or other 3. Keep calm and do not argue. parties involved to the Brennan main office. 4. Make no statements concerning guilt or fault. 8. Fill out the standard Brennan accident form and take photos to send with your reports. 5. Never agree to make payments for the accident.

Kansas City Southern Railroad Loggy Bayou L-589.6 Strike Repairs By Derek Armstrong Kansas City Southern Railroad contacted Brennan shortly after being notified that a material barge loaded with rock had impacted one of their railroad bridges about 45 minutes south of Shreveport, Louisiana. We immediately dispatched a dive crew to inspect/survey the damage and report their findings to Westbrook Associated Engineers with whom Brennan partnered on this design-build/repair project. Repair Methods We Used: » Rapid Emergency Response » Diving Services » Design-build Construction » Temporary Rail Bridge Support » Survey Work » Rail Bridge Support Fabrication in Field » Crack Monitoring » Steel Pile Fabrication & Installation Using Vibratory and Impact Drivers » Rail Jacking

The Brennan crew (led by Robert Brand and Jeremy Kroll) CHALLENGES immediately began mobilizing marine equipment and personnel ENCOUNTERED: to the site. When they arrived on-site, the crew started welding 42 IN diameter pipe together to make the 80 FT long pile. » Rapid Mobilization Simultaneously, crews were welding 24 IN diameter pipe into Response: Divers were 50 FT long piles to be used to as a template for the 42 IN on-site inspecting damage diameter piles. After the piles were welded to the required lengths, to the bridge within 24 the crew started welding together 36 IN tall beams that weighed HR of being contacted 300 LB/FT. The beams were welded along with required stiffener (including a 16 HR drive plates, jacking supports, and pipe bracing that were installed from the home office). on top of the 42 IN diameter piles and ultimately support the rail bridge girders, allowing the damaged concrete column to » Design-build aspect of be demolished and reconstructed without disrupting normal rail the work required multiple traffic. versions of the planned work. Thank you to the entire crew: Robert Brand, Derek Armstrong, Jeremy Kroll, Jonathan Anding, Dave Scheall, Jim Balonis, Brad » Delivery of significant steel Kensmoe, Orie Anderson, Chase Smith, Travis Deflorian, and on very short notice at a Jon Thompson. time when steel supplies are low. Project Statistics: » Approximately 1,000 LB of welding rod was used in » Active train traffic during construction. fabricating items for this project. » Impending high water and » Over 1,200 LF of structural welding was performed. desire to get trains back » Over 250,000 LB of structural steel installed/fabricated for to track speed required accelerated schedule. this project (steel pile, support beam, stiffeners, bracing). » Zero rail delays during construction. » Daily planning was required because of the remote location (not near a major city). » Local welding supplies were pushed to the limit. » Local wildlife hazards (alligators, snakes, and fire ants) were abundant.

By Mike Binsfeld In the first half of 2021, we shook things up a bit. To overlap. The individual skill sets the groups possessed be more accurate, we brought things together. For grew to a point where the folks in 1 group could very the first time in our history, we’ve combined 2 of our easily assist those in the other with their work. operating groups. To bring about more efficiency, to provide more opportunities for those within the Then, earlier this year in discussions with Jeff Steiber, groups, and to be more competitive, the Civil & Rail he expressed an interest in transitioning into more of group is being combined with the Structural group to a resource role that would benefit Brennan along with form a single entity called the Construction group. our clients, subcontractors, and vendors as a whole. As we worked to define a role for Jeff that would As everyone is aware, both the Civil and Structural leverage his extensive experience in the industry, the groups experienced tremendous individual growth reason to combine the groups became even more over the last several years as they focused on their apparent. specific markets. We’ve worked hard to expand each group by taking on more diverse types of work, which We simultaneously began discussions with Zach led to outstanding opportunities for those within the Pontzer, who leads the Civil group, to formulate a groups. It’s understandable that on the surface, it may plan that would ultimately combine Structural and seem counterintuitive to combine the groups, and Civil under his leadership. As the plan developed, not too long ago, the idea of combining 2 operating it became clearer as to why this “tie-up” needed groups was met with furrowed eyebrows and snarls. to happen. We realized Structural and Civil were beginning to cannibalize each other’s work scopes, We’ve conducted much analysis and participated which led to issues determining which group was in many discussions with the folks in each group to going to tackle particular jobs. make sure this was the right direction. Through our discussions, we began to realize that as each group At the end of a year, each operating group is asked has grown, the type of work they chased began to to set a budget for the next fiscal year. That budget is based on data showing us how much work we believe

is going to be out there to capture, our available capacity Xcel Energy Powerline Replacement to do the work, and many other factors. Each service group works extremely hard to find enough work to keep Cofferdam installation Concrete demolition their people busy and to make their budget. You can see where overlapping work could cause problems! Cargill Muscatine Dock Midcontinent Railroad In addition, we realized that by combing groups, we Concrete Placement at Labrynth Wier could be more efficient with travel. For instance, we could avoid sending an individual from the Green Bay area to Duluth while having a different individual who lives in Duluth travel to Green Bay (essentially crossing paths) simply because of the group to which they belong. There are many areas where we could improve crew deployment efficiencies. For folks in the newly combined Construction group, we anticipate many more benefits for the future. Recognizing a common set of skills within both groups, while working toward building more well-rounded field leaders, operators, carpenters, laborers, engineers, and project managers has become a central theme in all of this. Training our people to tackle more types of work will not only make us a better company, but it also creates incredible value and opportunity for all employees. Continuity of training will allow team members to pursue various areas of work that may be of interest. Being able to respond to our clients’ needs with people who possess diverse skill sets, with multi-industry experience will better position us in the future. As we all know, new and varied types of skill sets will be necessary as we continue to expand and develop into new market areas. We are creating new positions because of the group merger as well. Matt Hogan has stepped up to fill the Construction group director position and we envision 2 additional director roles in the very near future. We will also pursue new types of work in the areas of foundations, wire sawing, transmission, rail, and other geographic locations. A tiered system for project engineers and project managers will also be implemented through a comprehensive talent review process that has already begun with the Human Capital group. The goal for the talent review process is for each team member in the group to have a thorough understanding of where they sit currently with their skill sets, and to define with us where they want to take their careers at Brennan. From a human capital standpoint, this is one of the most exciting things we’ve undertaken as a company. We fully expect that after both groups fully integrate together, we’ll be a tougher competitor in our markets and the people within the Construction group will have a clearer vision as to where their careers are headed at Brennan.

A Underwater Services participated in a successful New yet complex design-build project in South Dakota. Source of Drinking In November 2020, Brennan was awarded a subcontract with PKG Water Contracting, Inc. (PKG) to perform the marine work portion of a contract with the City of Pierre, South Dakota. We learned about for the City the opportunity when PKG reached out to us after their initial marine of Pierre contractor declined the contract. By Wyatt Eaton We provided them with a proposal, and they selected us to perform the work. As the marine contractors, we needed to install a new 765 FT long intake line in the Missouri River. The purpose of the new intake line was to provide the City of Pierre with a new source of clean water as their current well system was not able to provide a desirable quality of water. Brennan teamed up with Viking Helical Anchors and Machin Engineering Inc. for the design-build phase of the project. This phase included designing the helical pile foundation and steel pipe supports. A considerable amount of effort was put into this process so that all connection work could be efficiently performed underwater with divers. After the designs were solidified, we focused on the water intake itself. The 765 FT long intake pipe in-river end of the intake line has a large screen; the other end runs into an on-land caisson (the pump station). The project required dragging the entire 765 FT long pipe into the river and then pulling it back through the 3 FT diameter bore hole in the riverbank that was drilled by Central Trenching, Inc. This pipe will convey water from the Missouri River to the city’s new raw water holding tank. To support the pipe, Brennan installed 12 helical pile bents underwater: 38 piles total, 14 of which were battered at 45 degrees to provide lateral support. Ten of the pile bents received a support beam that spanned between each pile that had a cradle for the intake pipe. The last 2 bents received a square structure that supported the various steel pipe fittings and the screen. All of Brennan’s work was performed from a floating marine plant. Large helical head “ The planning needed to accomplish this is far more advanced and intricate than you might imagine… I was astounded by the technology, technique, and expansive ”planning necessary to connect that intake pipe to our infrastructure on land. Steve Harding, Mayor of Pierre

We experienced several challenges during Divers making tieback connections back to the support beam this project: Intake pipe end 1—river end » A dam located approximately 5 MI upstream from the Intake pipe end 2—screen end project caused ±3 FT to 5 FT fluctuations in water Pulling the intake pipe into the river levels throughout each day and directly affected current forces on our divers. » Wind affected crane use during mobilization and demobilization. » Without soil borings for the area in which we drove pile, we did not know what we’d encounter. We hit a lot of rock in the 5 bents closest to shore, making it difficult to keep 4 FT spacing on the pile bents. These unpredictable conditions also caused misalignment on some tiebacks and made it challenging to keep the verticals plumb. » Cutting the PVC intake pipe proved difficult, as well as ensuring a sufficiently straight cut for proper installation of the MEGALUG® mechanical joint restraint. We exercised extreme care in taking weight off the drop piece to prevent spider-cracking down the pipe. » As pile extensions were added, it became increasingly difficult to keep the battered piles in the template and straight. » The unpredictable nature of the directional drilling contractor’s work (e.g., large rocks or other obstructions in their path may ruin drill heads or cause course alterations) introduced complexities into our schedule as well. This was one of the more complex underwater projects that Brennan has done, not to mention fast-paced. The crew did an exceptional job keeping their heads in the game despite the long hours and weeks. This project was an impressive accomplishment that has opened the door to future work with new clients. Thank you to all involved for your hard work and support. Project Team » Project Manager: Wyatt Eaton » Superintendent: Mike Weiers » Dive Foreman: Pat Rude » Divers: Max O’Meara, Aaron Rowling, Cory Harris, Mike Converso, Will Martin, Aaron Taber, Christian Boone » Operators: Eric Boldt (Excavator), Luke Fuchsel (Tugboat), John Aase (Crane) » Dry Crew: Pete Schaffer, Jim Balonis, Dan Lloyd » Surveyors: Taylor Blumenstein, Jack Radenz

Lock #14 Mississippi River Guide Wall Modifications By Ryan Curtis Lock & Dam #14 is located near LeClaire, Iowa on the Upper Mississippi River above Davenport, Iowa, and Moline, Illinois. J.F. Brennan Company, Inc. (Brennan) was subcontracted by General Constructors, Inc. (GCI) to assist in updating the Mississippi River Project Office of the United States Army Corps of Engineers (USACE), Rock Island District. BRENNAN’S WORK INCLUDED adding approximately 800 LF of a new gravity wall and topside steel dock structure and installation of 12 new mooring pile structures to secure the USACE fleet. Following the early 2020 completion of our upstream guide wall scopes of work, a late 2020 contract modification was extended to Brennan for the downstream guide wall. The guide wall is expected to be completed by September 2021. As a major subcontractor, Brennan had several tasks: » Demolition and removal of existing timber cribbing » Mechanical dredging of materials from a marine plant » Drilling and installation of temporary soldier pile from marine plant » Installation of precast panels for earth retention » Installation of sheet pile » Dive team inspection, cleaning of underwater portion for precast panel, and soldier pile removal Demolition and Removal of Existing Timber Cribbing Brennan used a 470 Caterpillar® Backhoe with a thumb bucket to remove the existing timber cribbing and backfill beneath the water. The backhoe was placed on a portable barge. The materials that were being removed, were loaded into a rock box, and hoisted to land via crane for disposal.

Drilling and Installation of Temporary Soldier Pile from Marine Plant Brennan contracted Taylor Ridge Drilled Foundations, Inc. (Taylor Ridge). to drill the temporary soldier piles to a depth of nearly 25 FT. After the holes were drilled, casings were placed into the hole where then Taylor Ridge drilled a socket into bedrock into which the soldier pile was concreted. Dive Team Jumps In Brennan's on-site dive team performed the underwater inspection for the precast panel installation. The team made sure the areas being inspected were free of any materials, debris, and sealed for concrete placement. They also assisted with the removal of the temporary soldier pile. Guide Wall Modification Challenges The Brennan team faced several challenges with this project to date. One of our biggest challenges includes the area in which work is being performed. We are sharing the site with other contractors doing land base construction as well. The area is very congested and makes it challenging to make moves, get equipment in and out, and receive deliveries. Safety is our number one concern with all the moving equipment in this area. We are constantly making sure the work areas, and our workers, are safe and clear of overhead crane movements and moving equipment. Thank You! A much deserved and special thank you to the entire Lock #14 Guide Wall Modification team! We’re also thankful for the cooperation and support from our project partners, especially GCI, the USACE—Rock Island District, and our suppliers.

MOLYBDENUM AND MUD By Gayle C. Edlin Metaphor—referring to something as if it actually were another thing—tends to create memorable comparisons. Not only does drawing on the familiar help others make sense of the new or unusual, it also aids in strengthening our own understanding as we form explanations. As you might expect, people tend to favor representations that relate to their own experience, which leads to things like … well, this. MOLYBDENUM Recently, someone—we’ll call this person Random Question Guy1 (RQG)—asked me if I had a favorite element on the periodic table. As my undergraduate degree included a hefty chemistry minor, I did not hesitate to name molybdenum. In fairness, it must be noted that I butchered the pronunciation, and failed to adequately justify my selection. Later, the following email exchange occurred2: Me: “I forgot that it’s also atomic number 42. Which is, of course, the answer to the ultimate question of ‘life, the universe, and everything’ as well.” RQG: “Ah very interesting” Me: “Please tell me you get the reference.” RQG: “I do not” Me: “… sorry, of course not. You’re not a nerd.” This admittedly arcane example nevertheless illustrates the importance of knowing one’s audience. How we communicate—and commensurately, how those we’re speaking with or writing to react to the information that we impart—depends on choices we make. The point is that a person who hasn’t read Douglas Adams’ comedic science fiction classic, The Hitchhiker's Guide to the Galaxy, cannot be expected to know that the answer to the “Ultimate Question of Life, the Universe, and Everything” is 423. Similarly, a person who isn’t familiar with specific equipment or techniques will not understand their importance to completing certain scopes of work as easily as someone with comprehensive technical expertise. If you’ve ever explained a task you perform on a regular basis to someone who lacks similar experiential framework, you’ve probably gotten a blank look at some point. Work we do often—even complex processes— rarely registers as difficult to us because of all the practice we accrue over time. Try to tell someone else how to do the same thing, however, and you’ll often bump up against barriers of background, terminology, ability, and even interest. In face-to-face discussions, these factors register more readily, transmitted through both non-verbal cues and vocal interruptions that make them easier to spot and address. Written formats like email, on the other hand, give us a chance to review material while delaying our opportunities to clarify information sent or received. Writing benefits from anticipation and preparation. When you need to write, by all means, get your ideas onto paper as quickly as possible—convey the information as you see fit. Then take that first draft and consider your intended audience. What previous exposure would they have—or not have—to the information you just conveyed? Imagine reading your message without your specific background—would you still understand it as written? This reflection, and subsequent editing, may make the difference between building a clear bridge to connect with your reader and muddying the proverbial water.

MUD Speaking of mud … while slogging through a thick layer of the stuff on a local trail, I had the following “conversation” with Random Robin (RR): Me: “Don’t give me that look.” RR: … “Robin” isn’t a nickname. I was talking to an actual bird. (It happens.) The preceding day included a pristinely blue sky, bright sunshine, and more than enough people to make this introvert seriously question her decision to take a walk; only one day later, and the scene could not have been more different. The robin’s concerned stance likely reflected an evaluation of his own safety rather than consideration of why a single human elected to trek through cold, incessant rain, but it still caught my attention. Reflecting on the changing conditions of the atmosphere and how that affected trail use, it occurred to me that communication works—or doesn’t—similarly. Whatever a writer can do to improve the chances of connecting with an audience increases the likelihood that the reader will engage, even if they encounter some “mud” along the way. Speech, by the way, also follows this metaphoric path—unless you’re talking to birds. Everyone brings unique skills and expertise to discussions we have and messages we prepare. Our ability to share these ideas may depend less on our knowledge than on awareness of how other people might receive the information we share. While no form of communication or particular method guarantees success, when you take time to evaluate goals, consider who you’re addressing, and think about how your words might be interpreted by that other party, you do a lot to improve the path for them. In the end, it doesn’t really matter who looks at you funny, as long as you keep making strides to build understanding. 1. If you know, you know. 2. Reprinted with permission. 3. See also: https://www.dictionary.com/e/slang/42/

Company Milestones CHASE SLABAUGH WINS 40 UNDER 40 AWARD In May, Brennan General Superintendent Chase Slabaugh was recognized by The Waterways Journal in front of a large crowd at the Inland Marine Expo (IMX) in St. Louis, Missouri. Chase received his IMX 40 Under 40 award for his dedication to the marine industry. The IMX 40 Under 40 Award is presented to 40 men and women under the age of 40 who have made outstanding contributions to the inland marine transportation industry in a variety of fields. Congratulations, Chase! HIGH-RANKING MAJOR GENERAL VISITS OTTER CREEK REMEDIATION SITE Major General (MG) William H. Graham, the Deputy Commanding General for Civil and Emergency Operations with the U.S. Army Corps of Engineers (USACE) stopped in for a tour of the Environmental group's Otter Creek project operations. Brennan's commitment to safety and day-to-day safe practices were the main topics of conversation. MG Graham noted how impressed he was with the team’s emphasis on safety and well-organized project operations. He brought with him Jaime Pinkham, Assistant Secretary of the Army—Civil Works, Lieutenant Colonel Eli Adams, as well as Ashley Binion-Zuccaro, and Mark Schwab—also with the USACE. We're honored by their visit and grateful for projects and opportunities like these. Great work, Otter Creek team! PROFESSIONAL ACHIEVEMENT AWARD Chairman of the Board Tony Binsfeld has been awarded the 2021 Professional Achievement Award by the Opus College of Engineering at Marquette University. The university presents this award once per year to an alumnus proving to make a positive difference in our world. Congratulations, Tony!

DREDGER of the Month The Dredger of the Month Award recognizes employees within the Environmental group who go the extra mile in their work. Nominations can come from any employee by submitting a short description of how that person has gone above and beyond expectations. The Dredger of the Month committee reviews all submissions for the month and votes on which nominee’s exceptional work ethic or innovative idea stands out the most. Each monthly winner receives a gift card to the Brennan Store. Nominations can be submitted directly to General APRIL Superintendents, Tyler Lee, Dustin Bauman, Mike Wyatt, and Greg Smith. Dan McCauley and Kyle Pattison (building a remote-control survey vessel) MAY Dave Pradovic Jr. and Nate Volz (great dredge production) JUNE Taylor Looker (great leadership) and Taylor Blumenstein (rocking an excavator GPS setup)

Tr aining That Broadens Brennan Capabilities Offshore By Mike Cannell | Photos by Ryan Midwood J.F. Brennan Company Recently Brennan partnered with the largest constructor of (Brennan) offers a offshore wind farms in the world to perform topside and dive work diverse set of service related to subsea cable decommissioning and removal. Based offerings to our clients, on client requirements, all employees on site must have current all of them tied to training under Basic Offshore Safety Induction and Emergency water. It’s been said Training (BOSIET), Global Wind Organisation (GWO), or that Brennan works on, Standards of Training, Certification, and Watchkeeping (STCW). over or under the water through every season Based on availability, distance, class size, and timing constraints, of the year. Because of Brennan chose to work with Northeast Maritime Institute (NEMI) this, the training required based in Fairhaven,Massachusetts, to provide training under the based on the hazards we STCW standard. identify, or by our clients, is also comprehensive. Because of COVID-19 concerns, class sizes have recently been limited to 14 students per class and the first 14 employees were selected from the Rhode Island office to make up the initial class and be the crew for the upcoming project. As currently delivered through NEMI, the STCW coursework involves 24 hours of classroom time which was delivered online in 60 plus instructional units covers topics such as maritime standards for watchkeeping, first aid, fire protection and firefighting, survival at sea, and many others. This is followed by 8 hours of water survival training and 8 hours of firefighting training, both in a hands-on practical application format.

Water survival training was held at the Wareham, Massachusetts, YMCA using their indoor pool. Students practiced using different flotation methods and equipment from personal flotation devices to improvised methods such as using coveralls or even pants filled with air. A significant portion of the in-water training involved the use of immersion survival suits. Firefighting training was held at the Connecticut state fire academy in Windsor Locks, Connecticut, and taught by the staff there. Employees received instruction on firefighting protective equipment, proper fitting, and use as well as deployment of water and foam systems for fire suppression. Everyone took their turn in every position on their respective teams to attack and extinguish fires outside and the day was capped off with making entry to attack fires in the burn building and to retrieve victims. Most of the employees who attended the course had little experience with many of the topics and especially the practical application portions. The hands-on training provided realistic scenarios to exercise skills gained in the classroom and provided employees with the confidence that they had solid training to handle a similar scenario Brennan is focused on meeting or exceeding client expectations and requirements. Although STCW training was a client requirement to access the project site in this case, it won’t always be a requirement for similar work. What STCW and any other correctly chosen training does for us is to provide more skills to operate safely, making us more versatile as an organization. Work in the offshore wind energy sector is poised to experience tremendous growth in the coming years— employee certification in this area positions Brennan to be a safe and reliable resource to major players in this industry.

Game Changers: ITnhenBorveantniaonn Program GRASSE RIVER REMEDIATION—SLINGIN’ SAND INNOVATION Submitted by Sam Crawford Innovation Contributors: Brad Tenor, Cole Lorenz, and Greg Arneson When sticky sand runs through the Broadcast Capping System (BCS™), it tends to plug up the chutes. In years past, crews used a spray bar fed by numerous garden hoses to prevent plugs. These hoses cluttered up the deck and proved difficult to direct water exactly where needed to lubricate the chutes and keep sand moving through them. Brad Tenor, Cole Lorenz, and Greg Arneson came up with a new design to use at the Grasse River project. Their design is fed by a larger pump and consists of flexible copper tubing which allows the spreader operator to specifically pinpoint the area that tends to plug. This innovation has led to significantly fewer chute plugs and thus less reduced downtime associated with clearing out the chute.

‹‹ Live Well, Work Well ›› Pet Safety: Poisons PROTECT YOUR BUDDIES FROM HOUSEHOLD HAZARDS If you are a typical pet owner, your dog and/or cat is a part of your family. However, just as you would with a baby, you must be vigilant in protecting them from poisonous items that can be found around the house. POISONOUS PLANTS PEOPLE FOOD IF YOUR PET IS POISONED... Those sweet-smelling flowers As much as your pet begs for a or cascading green plants may taste of what’s on your plate, it is Call the Animal Poison Control brighten up your home, but generally not wise to feed your Center at 888.426.4435. Be ready unfortunately dogs and cats are animal food or drinks meant for with a description of your animal, attracted to them too. The most humans. That which is especially symptoms, information about popular flora also dangerous to harmful to pets includes: the poisoning and, if applicable, your pet are: have the product’s label or » Grapes container handy. The ASPCA » Lilies » Raisins also recommends having a pet » Tulips/Narcissus bulbs » Avocado first aid kit, containing hydrogen » Azaleas/Rhododendrons » Chocolate peroxide (3%, to induce vomiting), » Oleander » Onions, garlic, and chives a bulb syringe or turkey baster (to » Amaryllis » Coffee administer the hydrogen peroxide), » Chrysanthemums » Alcoholic beverages saline eye solution, artificial tear » Daisies » Undercooked meat gel, forceps, a muzzle (to prevent » Baby’s breath » Raw bones (they can splinter) getting bitten if your animal is » Pothos of the Araceae family; » Products sweetened with in shock), a mild dishwashing liquid (to bathe him/her after skin is an extremely popular xylitol (like sugar-free gum) contamination), and a can of your houseplant pet’s favorite food. You can also MEDICATIONS purchase such kits in pet stores or All of the above can produce online. vomiting, diarrhea, loss of Everyone has dropped a pill on the coordination, and in some cases floor from time to time. However, if Did you know...? even coma or death. This list you have pets, you need to pick it is not exhaustive; for a more up immediately; if you cannot find The ASPCA Animal Poison comprehensive record, visit it, get out the vacuum. Never leave Control Center handles more the American Society for the opened medication out on the than 140,000 cases of animal Prevention of Cruelty to Animals counter. Also, if you are dispensing poisonings every year; 60,000 of (ASPCA) at www.aspca.org. medication to your animal, make these calls usually involve human sure to read the instructions medications or the incorrect Source: ASPCA carefully. The ASPCA has also administration of veterinary received calls regarding poisonings medicines by pet owners. by well-meaning pet owners.

And We’re Back— Another Great Start on Lake Neshonoc By Vic Buhr The Brennan crew is off to a Brennan has previously performed dredging at Lake Neshonoc in great start at Lake Neshonoc 2001 and 2002 for the Village of West Salem (the Village). At that time, in West Salem, Wisconsin. the contract involved building the confined disposal facility (CDF) and Work began in fall 2020, dredging 800,000 CY of sand and silt from areas all around the lake. and dredging operations This time around, we are working with the Village again as well as commenced on May 17, 2021 Cedar Corporation, a Wisconsin-based company acting as the design after a winter break. and oversite engineer. When the first phase began in 2020 for our current Lake Neshonoc project, our team worked to strip and stockpile topsoil, install weirs, and reshape the old CDF from 2002 to allow it to accept dredge material. Water quality is always a challenge during a project like this, so the crew implemented a pair of new Brennan designs that to date are working very well. Ryan Curtain, Adam Trofka, and crew launching the dredge

Initially, this project started out at 400,000 CY Cletus Bowe running a safety meeting of dredging. But because the Village was able Jason Steiber to acquire additional funds, 100,000 CY was added to the scope. As of now, production is somewhat exceeding the bid rates and if all goes well, the dredging portion of the project will conclude by late fall 2021. The areas we’re dredging include a large sediment trap, and the South and East Fishery. Last year, we also spent some time reopening a boat landing area that had silted in. We’re utilizing the Dredge Kevin Zenke on Lake Neshonoc, an idler barge with an HP booster, plus a dozer and excavator on land. We have 2 crews who are working 12 HR shifts 5 days per week. Brennan team member Del Groth was Superintendent during the first Lake Neshonoc project nearly 20 years ago and is filling the same role again this time! He has been threatening to retire, but just couldn’t resist the chance to work closer to home and dredge Lake Neshonoc 1 more time. Although most of the original Lake Neshonoc crew who worked for Del on the first project have since retired, he has a fine crew of seasoned veterans on board for the current project, including Ryan Curtain, Adam Trofka, Jason Steiber, Steve Delaney, Charlie McNally, Zack Hermeier, Jess Hartman, and Jesse Wilk. After dredging is complete this fall, the last phase of the project will include shaping the CDF, spreading topsoil, and final seeding. All work is scheduled for a late spring 2022 completion date.

Brennan IT Department Is Growing! ByBrianJerzak The Information Technology (IT) department has been very busy this year so far. Here are a few notable projects that we have completed. East Coast Office Mid-South Office » Rewired the office with 22 additional data » Wired office to accommodate 20 data terminations terminations » Increased the internet bandwidth » Installed a fiber internet connection » Installed new network equipment and » Installed new network equipment and connected it to La Crosse HQ connected to La Crosse HQ » Installed 4 cameras » Installed 5 cameras » Installed 2 wireless access points » Installed 2 wireless access points » Outfitted 2 on-site job trailers with additional Boston Office workstations and connected the trailers via » Moved the entire network and all associated wireless bridges back to the main office network equipment Including workstations, cameras, and audio video to a new office in the same » Setup new employees in Active Directory® and complex created Brennan email accounts » Provided phones, computers, and mobile devices as required Please contact IT well ahead of all job startups for which you need any of the following equipment. We are seeing extended leads time on this equipment and we will need to place orders much earlier than normal. » Cameras—Wired/Wireless » Hotspots » Printers/Plotters—Large and Small » Network Equipment—Wired/Wireless » Cradlepoint Cellular Internet Routers » Monitors/Docking stations Fun Recent Security Brennan Facts Initiatives Service Desk » We have 325 users in » Dashlane™ Password Since January 1, 2021, Active Directory Manager (Password we have received over Vault) 1200 tickets in our » We manage over ticketing system. On 350 computers » Microsoft® Office 365— average, we receive 2-Factor Authentication approximately 10 tickets » We manage over (2FA) per day. 675 mobile devices, including 200 iPads® » Cisco® Secure Endpoint Protection (Cloud- Managed Security Solution) 1 2TWO WAYS TO SUBMIT A SERVICE DESK TICKET Go to https://support.jfbrennan.com Another method to submit a ticket a. Select single sign-on. is to e-mail [email protected] b. Enter your domain user account and enter brief description of your request in the subject line. and password. c. Sign in.

DUE TO COMPANY GROWTH, and the people and systems we support, we’ve made some recent changes in our department roles and responsibilities as follows: Jeremiah Shaver has been promoted to IT Operations Manager and will oversee all aspects of Brennan Service Desk. We hired Scott Pooler, a full-time employee (FTE) to be the first level of support for all tickets received into our system. If the first-level support technician cannot resolve the issue or needs additional help, the ticket will be escalated as required among other IT staff members. Boy Yang was brought on board as a part-time IT Help Desk Technician intern to assist Scott. Tyler Stanek will be assuming new responsibilities to focus on software support and upgrades, including Office® 365 and SharePoint®. Tyler will no longer be working the front lines of the Brennan Service Desk. One Team with Two Focuses! Data/Software Focus Infrastructure Focus TORI WEISSENBERGER BRIAN JERZAK » Software-related » Strategic planning strategic planning and » Budgets and capital policy management expenditures » Project lead for major software » Corporate security initiatives and implementations » Disaster recovery » Oversee software JEREMIAH SHAVER administration and security » Oversee and manage all aspects of WILL TWEED Brennan Service and Help Desk activities » Database administration » Server maintenance and support and support » Application maintenance and support » Network performance monitoring » Business Intelligence » Infrastructure troubleshooting and support » Active Directory/Microsoft® Azure » Group policy » Data query and reporting requests SCOTT POOLER » Data integrations and » Hardware/software needs troubleshooting » Ordering of IT Equipment » Phone/iPad™ setups » Software project support » Computer setups » Workstation setups/office moves TYLER STANEK » Printer troubleshooting » Software technical BOY YANG support and upgrades ◊ HCSS—E360, HeavyJob, » Hardware/software needs HeavyBid » Ordering of IT Equipment ◊ eCMS » Phone/iPad™ setups ◊ BMI Compass » Computer setups » Workstation setups/office moves » Office® 365 and SharePoint® » Printer troubleshooting administration » Software project support » Software asset management and licensing

Brennan Gives Back The Brennan Gives Back program was created to help Brennan “give back” to the communities in which we operate. The Brennan Gives Back committee, which is made up of employees from various backgrounds and locations, meets monthly to review and discuss the giving opportunities that are submitted via our webpage. If you have a cause or event you are passionate about, you can submit a request on the Brennan Gives Back webpage for consideration! we roercgenantliyzastuipopnosrted La Crosse Kiwanis Club Brennan is the partner sponsor of the La Crosse Kiwanis Club Flag Project. The Flag Project promotes patriotism and awareness of the Kiwanis Club in our community but also helps to raise money to support their youth-focused programs. American flags will be displayed at Veterans Freedom Park on Clinton Street and Roellig Park on Losey Boulevard in La Crosse on Memorial Day, Flag Day, Independence Day, and Labor Day.

Valle Catholic School Early Childhood Development Center Brennan donated to Valle Catholic School located in Ste. Genevieve, Missouri, to help them provide laptops for pre-kindergarten students to better prepare them for their transitions into a virtual learning environment. La Crosse River Clean Up On May 8th, Brennan sponsored the 28th annual River Clean Up in La Crosse. This annual event draws in volunteers who have pulled more than 700,000 pounds of trash and debris from La Crosse waterways. Down Syndrome Association of Minnesota–Tee It Up for Down Syndrome On June 23, Brennan sponsored the Down Syndrome Association of Minnesota’s Tee It Up for Down Syndrome Golf Outing which provides funding to support the organization’s mission to empower individuals and families, create community, and celebrate the abilities of people with Down Syndrome. Couleecap— Putting an End to Homelessness Golf Outing Couleecap works to fight poverty and promotes self-sufficiency, economic development, and social justice. Brennan sponsored their Putting an End to Homelessness Golf Outing on June 21 to help support Couleecap’s mission to make a difference in the lives of people and families throughout the Coulee Region. Ability Building Center The Ability Building Center provides services for individuals with disabilities through community inclusion. Brennan sponsored their “Best of the Fests” event on May 22 in an effort to support adults with disabilities in Houston County, Minnesota.

Years of Service Anniversaries 5 Years 05/23/2016 15 Years 04/03/2006 20 Years SAMUEL DUNN ERIC HANSON 04/27/2006 05/02/2011 CHAD DEFOE 05/22/2006 JASON STEIBER 05/02/1996 10 Years 05/13/2011 TYLER LEE BRIAN JERZAK 05/27/1996 LUCUS FUCHSEL BRANDON RASK KIAH ZIELLS 04/19/2021 ENVIRO INTER New LUKE LEVENE 04/26/2021 LABORER Hires NATHAN VAN WYK 04/26/2021 OPERATOR DUSTIN PAYNE 04/27/2021 DECKHAND JASON DUFF 05/4/2021 MATE CRAIG MILLS 05/4/2021 LABORER JONATHON BENEPE BISCHOFF 05/10/2021 OPERATOR DANIEL WHITE 05/10/2021 OPERATOR CLIFFORD GRANT 03/2/2021 PILE DRIVER ALEX GOETZINGER 05/11/2021 YARD LABORER CARPENTER MATTHEW NOLAN 03/8/2021 PILE DRIVER KATERINA HOUSER 05/11/2021 ESTIMATING INTER SR PROJECT MGR CURTIS LAFLAMME 03/15/2021 FOREMAN MANUEL ELGUERA 05/12/2021 OPERATOR PILE DRIVER MICHAEL RHODES 03/15/2021 DIVE EQUIPMENT MGR DONALD RICE 05/12/2021 LABORER OPERATOR MICHAEL TURNER 03/15/2021 MECHANIC COLTON SCOVIL 05/12/2021 LABORER SUPERINTENDENT JONATHAN HUTCHINS 03/17/2021 DECKHAND CHARLES CUSTER 05/17/2021 ENVIRO INTERN OPERATOR KURT RETHORN 03/22/2021 MECHANIC DANIELLE MAY 05/18/2021 SR PROJECT MGR HR INTERN TERRY SMOTHERS 03/24/2021 KEVIN BOGOLD 05/24/2021 OPERATOR DILLON HUNT 03/30/2021 ETHAN HANEWALL 05/24/2021 ENVIRO INTERN JAMES HACK 04/5/2021 TYLER PETRELLA 05/24/2021 OPERATOR CHARLES WILKES 04/7/2021 TYLER ROGERS 05/24/2021 OPERATOR DAMON HAMILTON 04/12/2021 SKYLER TRUMBLE 05/24/2021 ENVIRO INTERN HAROLD TRAVERS 04/12/2021 ZACHARY ENGLAND 05/27/2021 DECKHAND MADLIN MORGAN 04/19/2021 ERIK LENT 05/27/2021 OPERATOR Human Resources Leadership: Positivity We can complain because rose bushes have thorns, or we can rejoice because thorns have roses. Every day we come to the job site we bring our whole a shorter temper than usual. The goal is to remember selves. Some days that may mean that we are full of that the thorns also hold something beautiful and positive. roses, we are upbeat, we are ready to tackle the day What can we learn from the negative experiences, or including any negativity that may come our way. Other the mistake we last made on the job? It is important to days we may be full of thorns, we had a fight with our remember that we all have thorns, some are different than kids or our spouse—something in our personal life is others, but how we approach those thorns and appreciate not how we expect it. We approach the day with less the roses is what makes the difference. excitement, we are more on edge than normal, we have By Janelle Pogodzinski

YOUDeveloping Our Human Capital: Are Our Greatest Asset! By Janelle Pogodzinski As we venture deeper into 2021 and tackle our group We are also in the process of developing foundational, initiatives, I reflect on what it means to develop and senior leadership, mid/first level leadership, and functional invest in our human capital. We are investing in our core competencies. During end-of-year performance learning platforms with a long-term goal of developing review, your leader will share the competencies with you, Brennan University (an internal learning program). explain where they see your ability in each as related to We are also creating a talent management program. your current role, and discuss what you need to do to get Talent management is the full scope of human capital to the next level, should you desire to do so. processes to attract, develop, motivate, and retain employees. We are making great strides in the first In 2022, we will focus on the reviews for the craft 6 months of this year as we tackle these initiatives. employees and align the review process to a similar structure. Establishing competencies and linking them We started providing training through our Anchor to each job type allows us to use those competencies system: discrimination and harassment, diversity, and a in selecting the best people for the job and onboarding drug-free workplace. In addition to compliance-related them appropriately, followed by developing, coaching, and items, we also invested in online leadership learning for helping each person find the roles that make them happy, all employees who have direct reports. This learning is productive, and wanting to stay long-term. Reviewing available when the learner needs it provided in short competencies with every employee also assists us in video format so that individuals can elect to watch many tailoring Brennan University offerings based on where we or few topics as they choose. As stated in The Brennan have the most need. Way, “Our future success relies on the continuous development of employees skills. We operate in an We are a growing organization. We have many environment where we serve as mentors, provide employees who advanced their careers during their time training, and strive to improve every day. We give open with Brennan. Nick Reis joined the company as a Project and honest feedback so we can further development Manager, became an Estimator, and is now the Director by learning from experience.” We recognize that our of Project Controls. Kyle Trocinski started 6 years ago as leaders need training so that they can continuously a Yard Laborer, then Yard Foreman, then Maintenance develop their skills. Coordinator, then Logistics and Yard Manager. Fifteen years ago, Dan Wibralski started as Project Manager Being a great leader includes understanding our and is now Vice President of Underwater Services. As employees’ strengths, opportunities, and where they Matt mentioned in his article, as the company continues aspire to grow in their careers. Therefore, the midyear to explore growth Brennan will continue to present new review has changed for all non-union employees, opportunities for interested team members. We will also Superintendents, and General Superintendents. Each provide support for those who are happy in their current leader will meet with every one of their employees to roles but want to continue to develop their skill sets. review their progress toward achieving their goals. They will also discuss what is going well for the “The capacity to learn is a gift; The ability to learn employee, where they need help, and where they desire is a skill; The willingness to learn is a choice.”1 to go in their career—both short- and long-term—as well as what the leader can start, stop, and keep doing ~Brian Herbert to help them be successful. It is important that you are open and honest with your leader about these topics We all must work together to develop and hone our Active communication with your leader will help them skills. Each of us are responsible for letting our leader identify how they can best help you develop in your know what we want out of our careers. Our leaders are role at Brennan via assignments, interaction, coaching, charged with providing us the tools, the resources, and and more. the feedback we need to grow our skills. This is Brennan’s pledge to each of our employees as we continue on this journey together. 1. Herbert & Anderson, Dune: House Harkonnen, 540.

True teamwork and problem solving skills at the Grosse Ile, Michigan, project that make us second to none. We had a task of setting blocks and with the current being so strong it was not going as planned, so the crew did an all stop and put their heads together to figure out plan B. Using what they had readily available as a “pen and paper” so to speak. Crew dinner in Duluth, Minnesota.

Search

Read the Text Version

- 1 - 36

Pages: