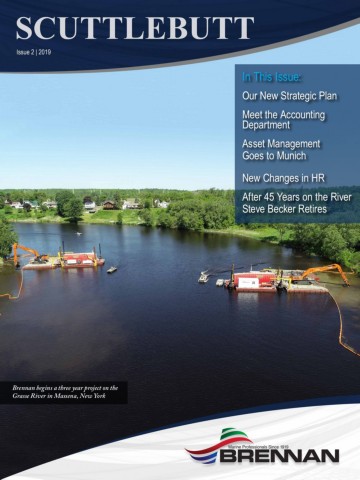

In This Issue: Our New Strategic Plan Meet the Accounting Department Asset Management Goes to Munich New Changes in HR After 45 Years on the River Steve Becker Retires Brennan begins a three year project on the Grasse River in Massena, New York

Our Challenge This winter and spring delivered nearly unprecedented precipitation throughout the Upper Mississippi and Illinois River Basins, leading to water levels not seen since 2001 or even 1993. Powerful storms wreaked havoc throughout the central United States, forcing officials to open the Bonnet Carre spillway three times over the last fifteen months, a first for that structure. Along the coastline, our country faces the loss of land due to erosion. Professional engineering organizations throughout the country are reevaluating the definitions of 100- and 500-year storm events, which often serve as the engineering basis for building modern waterborne structures. Unfortunately, our recent flood experience appears to be yet one more extreme in an amplified data set that now spans the better part of a decade. At the same time we deal with the effects of additional precipitation, we see a shift in in the demographics of the construction industry. Fewer people elect for a career in one of the trades and on a whole, our industry is aging as baby boomers move into retirement. These factors mean we have fewer of the skilled workers we need to secure our country’s infrastructure at this critical juncture. The recital of these problems is not to make a political statement of any sort. Rather, it notes challenges that we at Brennan have been actively managing all along. Both increasing precipitation levels and skilled trade shortages are real, yet unlikely to be at the forefront of most Americans’ minds when they think of our nation’s challenges. Addressing these problems are, however, at the foundation of Brennan’s new Mission and Vision Statements, which we constructed as part of our updated strategic planning efforts. Work on this plan has been ongoing for nearly a year and incorporated a great deal of feedback; this month, we are highlighting and releasing the plan to the entire company. In fact, we dedicated this edition of the Scuttlebutt to discussing our strategic plan and providing updates on progress we already made toward specific goals. OUR NEW MISSION STATEMENT READS: We create and execute innovative solutions to the world’s most complex maritime, environmental, and infrastructure challenges. The changes in our environment present us with a world-class challenge, one that requires highly skilled men and women working together to create and implement innovative solutions. In many ways, the solutions we execute on the Fox River, Grasse River, Holcim-LaFarge and other locations throughout the United States are emblematic of the inventive thinking needed in our country. Brennan’s mission is to build upon our past successes, designing and executing innovative ideas that address the greater challenges of our future. Ultimately, the solutions we construct will make life better for people living along or depending upon America’s waterways. Where the Mission Statement defines “why” we exist, the Vision Statement tells “where we see ourselves going.” OUR NEW VISION STATEMENT READS: We will be the best at delivering innovative solutions to the world’s most demanding environmental and infrastructure challenges. We will continuously develop unparalleled intellectual capital, redefining what is possible while setting the industry standard for safe and ethical practices. Our work will make Brennan the most respected company in our markets.

We plan to do the necessary work to be the best at Mission delivering solutions to difficult problems. Being the Statement best requires us to dedicate ourselves to developing and preparing people who deliver results, which We create and execute innovative is what we mean with the phrase “unparalleled solutions to the world’s most complex intellectual capital.” Together, we are well on our way maritime, environmental, and to achieving the goal of having the best people on infrastructure challenges. our team! We will continue to recruit and build our people, as well or better than we build our projects. Vision The difference between winning and losing work Statement hinges upon our ability to “think outside the box” and then implement our innovative thoughts through our We will be the best at delivering actions at the jobsite. Of course, nothing associated innovative solutions to the world’s with being the best is worth compromising our safety most demanding environmental and or ethical values; the ultimate human and social price infrastructure challenges. We will of reducing our high safety and ethical standards far continuously develop unparalleled outweigh any perceived benefit. As we have always intellectual capital, redefining what done, we remain dedicated to doing things safely and is possible while setting the industry the right way. standard for safe and ethical practices. Our work will make Brennan the most We don’t make changes to our Mission or Vision respected company in our markets. Statements lightly, or often. When we started our strategic planning efforts in 2018, we thought we would be leaving each statement unchanged from our previous plan. However, as we progressed through the planning process, we found that both the company and the challenges we face have increased in magnitude over time. Solutions to these greater challenges are rich with potential to benefit people within Brennan and beyond. Our new Mission and Vision Statements harness the significance of the problems we tackle in our work and compel the careful thought and well-executed solutions that will benefit us and our country. We have a well-defined mission and vision – now it’s time to get started! Matt Binsfeld President and CEO

SAFETY By Mike Cannell NEWHEALTH and SAFETY MANUAL Since the beginning of the year the Safety Group has been updating the Brennan Corporate Health and Safety Manual. Given our industry’s significant regulatory changes in the last two years, as well as Brennan’s growth, it was time. During the update, we reviewed regulatory requirements and how we assess hazards and conduct our operations. The result is an extensive but streamlined series of documents that are fully indexed and simple to navigate. HOW IS THE NEW HEALTH AND SAFETY MANUAL DIFFERENT FROM THE PREVIOUS VERSION? There are several ways that the new manual is different from the old: »» The new document layout from our Quality Management System requires each topic to be its own individual document. This makes it much easier to navigate. »» The documents are named precisely so users can find topics quicker and easier. »» Most of the narrative content has been removed and replaced with bullet points under logical headings and subheadings. This will allow users to quickly locate answers within the text. Find the documents here WHERE CAN I FIND THE NEW U: Universal Drive 1-QSuyasltietymManagement HEALTH AND SAFETY MANUAL? 03-WInosrtkructions 714-Safety The latest versions of all Health and Safety Manual documents will always U:\\1-Quality Management System\\03-Work Instructions\\714-Safety be available on both the iPad for HCSS Safety users and on the Universal drive.

IS THERE NEW MATERIAL IN THIS VERSION THAT WHAT IF CHANGES ARE NEEDED? WASN’T IN THE OLD MANUAL? A great aspect of the ISO-9001 process is that anyone Yes, there are several areas that contain completely who determines that a change or update is needed, new information, for example: they can submit a corrective action request. Typically, this is going to result in a change to the document in »» Protecting the Public. We have seen a significant question in less than a week. increase in work performed in urban areas and near the general public. This section was designed WHO CAN I GET IN TOUCH WITH IF I HAVE to address some of the issues we have run into QUESTIONS? while working in areas where we may have close contact with the public. Talk with the Safety Manager that’s working with your project or you can contact: »» Weather Impact on Operations. There have consistently been questions regarding if, when, or »» Vic Buhr IV – Site Safety Manager under what conditions weather becomes a factor 608.780.5544 |[email protected] that requires us to shut down operations. This new addition to the manual spells out requirements in »» Tim Butz – Field Safety Manager plain language to best ensure that common sense 608.799.3279 | [email protected] and good judgement rule the day. »» Dan Palen – Marine Safety & Compliance Director »» Diving. The previous Dive Safety Manual was 608.519.5270 | [email protected] about 30 pages of high-level information in one chapter. Diving is now covered comprehensively »» Steve Skau – Safety Director and broken out by specific types of diving activities 608.519.5269 | [email protected] in 11 different chapters. They’ll be able to answer virtually any HOW DOES SOMETHING AS SIMPLE AS A NEW question you might have! LAYOUT HELP THE PEOPLE IN THE FIELD? Within the new manual, topics that apply to everyone all the time are closer to the beginning. Areas that are activity or hazard-specific such as diving operations or awareness of certain types of chemicals are placed closer to the end. Also, all topics and documents have an identical layout, starting with the scope of the topic in the document and who is responsible to meet the requirements. The layout is direct and leaves little open to interpretation. HOW OFTEN WILL UPDATES OCCUR IN THE FUTURE? Since all the new documents are controlled under ISO-9001, we will review them annually. This means that ALL sections get reviewed once a year, minimum, and changes are made immediately following the review process. By contrast, our last manual was updated in 2015.

CIVIL EmA Meorthgere’snDacy y » The Civil Group Answers the Call « Flooding often leads to emergency projects for marine crews then brought in and assembled two marine plants contractors like Brennan. One of our latest opportunities using sectional barges. A 100-ton telescopic crawler crane to help a good client in need was with Xcel Energy (Xcel) was walked onto one of the barges, and then the barges in Chaska, MN. Chaska is a small suburb in the southwest were moved into place using a 600-horsepower truckable corner of the Twin Cities and is about 10 minutes away from towboat with Pilot Dave Majeski at the helm. our Shakopee office on the Minnesota River. In early May, Xcel found one of their 100-foot tall H-frame power line The next challenge that we faced was to locate a circa structures leaning at a 60-degree angle and hanging from 1930s 10-inch, 400-psi natural gas line that ran through the wires that it once supported. This H-frame structure the work area. Adam Thorson, the Dive Group Project supports a 115,000-volt double circuit line, which means it Coordinator, used a side scan sonar to gather underwater carries six energized lines along with two static lines which images of the work area. He was able to locate the gas act like a ground, one for each of the three-phase circuits. line so we could mark it and avoid damaging it with our equipment. The exact cause of the failure of the H-frame is unclear, though speculation includes scouring and undermining We then worked side by side with crews from Xcel to from the flooded river, or a collision with large pieces of quickly right the leaning structure back to vertical and driftwood. With the water elevation approximately 15 feet secure it. Xcel Energy crews then cut and lowered the over what is considered normal, power line structures like eight de-energized lines. With the lines off, our crews these can become very vulnerable to damage. used the telescopic crawler crane, two 120-foot aerial lifts and various Digger Derrick Trucks to cut the 100-foot tall Our first challenge was gaining access through a quarter- structure into smaller sections and safely lower them to mile of wetlands in order to reach the river. Xcel crews the deck of the barges. Superintendent Eric Von Arx and worked with the City of Chaska to cut an access road Pilot Jason Reggin pulled these pieces of the old wooden through the wetlands and then deployed roughly seven structure upriver where they were removed, and then hundred 7-foot by 14-foot plastic interlocking mats. Our floated new poles back to the site.

Overview of the project from a drone. Drilling the piles and poles and installing bolts to tie the This project required approximately (700) 7’ x 14’ wood pole to the steel piles. The heavy wood pole sets on a mats that interlock to allow heavy equipment to drive through the wetlands and access the river. small platform that is welded to the steel piles. A closeup of a finished steel piling support. Meanwhile, our crew drove six 60-foot long pipe piling with a vibratory hammer. The new H-frame power pole consisted of two 22-inch diameter cedar poles that required a separate foundation to support each side. Each cedar pole had to be driven into the center of a three-cluster of steel pipe piles that were driven approximately 45-feet into the ground. Our crew was able to keep the power poles to within an astonishing one inch of the desired design while ensuring it remained perpendicular to the line. With the foundations and poles in place, Xcel Energy crews added the cross bracing, wood arms, and insulators to the structure. Lastly, the crews spliced the lines and then raised and secured the conductors to the newly built structure. Once all the crews wrapped up loose ends and safely removed the barges from the area, the power lines were reenergized and placed back into service. Emergencies never seem to happen during the week, and this project was no exception. A special thank you is owed to all of the mothers who were not able to spend Mother’s Day with their sons or significant others because they were working on this project. Thank You for your understanding and support! Also involved in the project were Carpenter Jeff Ross, Operator Jesse Christensen, Crane Operator Brad Kensmoe, and Laborer Elliot Kowalczyk. This was taken after the structure was Often times the crews will “power into the bank” while loading This shows the leaning structure which supports straightened. The crews are going up to begin equipment from the river banks to help secure the barges. Additionally, the 115,000-volt (115kV) line that is hanging the demolition of the old structure. we used the jet boat to help keep the barge spread in place due to the from the wires it once supported. current. Typically, we’ ll use steel ramps that are 5’ wide and 40’ long.

Identif y, Pl a n, Execute, Succeed An Overview of the By Mark Binsfeld 2018–2021 Str ategic Plan Over the last 18 months, we created a robust plan to help guide Brennan through 2021. We made some big changes during the process, including updates to our Vision and Mission statements, as well as a revamp of our Cultural Tenets. We set lofty goals for each group and department, all of which will be accomplished over the next three years. WHY ARE STRATEGIC PLANS IMPORTANT? Strategic plans help us become a better company. We use our plan to develop a set of individual and group goals that will lead to overall corporate success. This ensures that everyone is working in the same direction and that we are held accountable to continuously improve the way we work.

THE ANALYSIS The last time we went through a full strategic planning process was back in 2014—a lot has changed since then. This time around, we did several deep dives into Brennan as an organization, and then into each of our 5 groups: Brennan Marine, Civil, Rail, Environmental, and Structural. We also included all of the support departments including Accounting, Human Resources, Safety, Asset Management, Business Development, IT, and Project Controls. in each analysis. To begin the study, we completed 3 strategic analyses: »» SWOT Analysis—Strengths, Weaknesses, Opportunities, and Threats impacting Brennan »» PEST Analysis—Political, Economic, Social, and Technological changes affecting Brennan »» Porter’s 5-Force Analysis—Competitive rivalry resultant from clients, suppliers, and competitors In addition, we constructed several detailed client profiles and completed a thorough competition analysis, pro- forma growth analysis, future opportunity analysis, and a corporate resource analysis focusing on people and equipment. After several days of intense discussion and review of corporate data, we successfully combined all our information and drilled down to 8 strategic areas in which we could focus our efforts. THE RESULTS: STRATEGIC OBJECTIVES Each strategic objective represents the most important areas in which we, as a company, need to focus to continuously improve. Each objective is broken down into Organizational Goals, then into Business Group Goals, and finally into Group Initiatives. Growing....Smarter Every initiative features 2018-2021 Strategic Objectives a set of measures and Objective 1: Objective 2: Objective 4: Objective 6: targets along with an People & Asset Operations assigned champion to Learning Management Market ensure its completion. Management In total, we created 1- Recruitment 1- Safety Management Growth over 200 Group 1- Implement an asset Initiatives that, when -Attract the best management program that -Find efficiencies for cost a. Enviro – group completed, will lead to employees for our pipeline savings, maintain EMR, superintendent for development the overall completion maximizes equipment of Business Group with focus on internal usage, delivers efficient achieve SUB M of staff Goals, which then roll promotions support to field and office b. Dive – mobilization up to the Organizational operations, and optimizes 2- Information Technology program to optimize use of 2- Retention current and future -Maximize utilization of people -Invest, build and maintain infrastructure needs. software, steering committee, our industry leading c. Survey – extension of workforce through Objective 3: support for all services Sales engagement, rewards and 3- Total Quality d. Accounting – increase career growth Effectiveness Management cash flow through org wide -Continual improvement for billing and payment efficiencies to maintain our processes quality standards as well as e. Operations – universal ISO Project Management software f. BMI – growth in other harbors Goals and Strategic 3- Performance 1- Brand awareness, client Objective 5: Objective 7: Objectives. Management management through CRM Project Financial – Enhance communication 2- Growth through and feedback so all staff geographic, market and Controls Growth know where they are and where they can go/grow service expansion 1- Enhance quality of proposals, 1- Growth of revenue and turnover process, engineering consistent margin to reinvest in services, job cost forecasting, job the business and provide closeout and tools to analyze bid rewards for employees and job metrics WHAT DOES THIS MEAN FOR YOU? We encourage group managers to share information about our updated strategic plan and how it will affect their teams. Many of these initiatives are already underway; you may notice them in the form of a policy change, or a new hire for a position that didn’t previously exist. Change can be difficult to spot in the moment, but each of Brennan’s initiatives represents a step toward achieving a greater goal. At the end of the plan, we will look back and see an organization that has truly evolved, changing for the better!

BRENNAN MARINE HIGH WATER By:AdamBinsfeld Keeps the River Industry on Its Toes EVERY YEAR, we anticipate high water in the spring as it is an inescapable fact that melting snow and spring rains bring high water throughout the Midwest. Many high-water events come and go with little fanfare while some wreak havoc. For many who were in La Crosse at the time, the flood of 1965 was the worst and has yet to see close competition. The same can be said for those affected by the flood of 1993 in St Louis. These floods topped or destroyed levees and the communities they were protecting. As of this writing, the flood of 2019 will crest near 46 feet on the St. Louis gauge, the second highest on record behind the flood of 1993 at 49.58 feet on the gauge. The folks that live in the Davenport area may speak of the flood of 2019 as the worst flood, beating 1993’s record by 7 one hundredths of an inch. For many though, the flood of 2019 will be unremarkable, except for those of us that work the river. As of June 1, the Upper Mississippi has been open to navigation for five days. On average, we could expect over 60 days of open navigation from St Louis to St Paul by June. Many well-seasoned rivermen have said they’ve never seen a flood like this in La Crosse, one that is mediocre in level, but relentless in duration. Confirming their suspicions, the National Weather Service reported the following high-water stats for La Crosse. The harbor in Ste. Gen saw some very high water this spring.

Still a beautiful view in St Gen at sunrise While these numbers MONTHLY RECORDS are specific to La Crosse, much of the »» Highest Monthly Average River Stage for Any Month: 13.65 feet in Mississippi, Illinois, April 2019 (previous record was 12.96 feet in April 1965) Arkansas, and Missouri Rivers share the same YEARLY RECORDS story. The Ohio River and Cumberland River »» Most Days in a Year at 10 feet or Higher: 77 days as of May 29 experienced prolonged (previous record was 73 days in 1986) high water through 2018 and into 2019. »» Most Days in a Year at 12 feet (Minor Flood Stage) or Higher: 47 days as of May 29 (previous record was 30 days in 2001) Through all the challenges that come »» Most Days in a Year at 13 feet (Moderate Flood Stage) or Higher: with prolonged high 36 days as of May 29 (previous record was 27 days in 2001) water, BMI crews in all locations have done CONSECUTIVE DAYS RECORDS an extraordinary job in keeping each other »» Consecutive Days at 10 feet or Higher: 75 days as of May 29, March safe, their vessels 16–current (previous record was 46 days, April 8–May 23, 1965) maintained, and the customers happy. »» Consecutive Days at 12 feet (Minor Flood Stage) or Higher: 41 days, March 26–May 5 (previous record was 30 days, April 12–May 11, 2001) »» 3rd Longest Streak at 13 Feet (Moderate Flood Stage) or Higher: 19 days, March 28–April 15 (record is 27 days, April 13–May 9, 2001)

CYBERCRIME IS VERY REAL, and it is important that everyone at Brennan knows how to stay safe and keep his or her information secure. Our IT Department, which includes Brian Jerzak, Jeremiah Shaver, and Tyler Stanek, put together a comprehensive list of industry best practices to help us avoid falling victim to cybercrime. From Brennan’s proprietary info to your own personal data – be sure to familiarize yourself with these Do’s and Don’ts when it comes to cybersecurity. Cyber S ecurity Starts W ith You! By IT Dept

Cybercrime Do’s and Don’ts Don’ts: Definite Do’s: »» Don’t use free or public WiFi »» Don’t use bootlegged free software »» Update passwords regularly and make them complex or apps »» Don’t use your Brennan passwords for »» Use a secure password vault »» Use dual factor authentication personal use »» Keep your personal and business emails »» Don’t click links to suspicious or malicious separate websites »» Utilize fraud alerts, credit lock, and »» Don’t post your location on social media »» Don't trust anyone – Be sure to think credit freeze »» Use protected external hard drives before you click a link »» Be wary of suspicious emails »» Don’t become complacent Brennan IT Policy Reminders Unacceptable use of Brennan technology includes: »» Using Brennan assets for illegal activity »» Software piracy »» Giving passwords to others »» Allowing unauthorized access »» Sending unsolicited e-mails (Spam) »» Transmitting obscene material »» Revealing proprietary info »» Posting to harm Brennan or its employees Warning: Construction Cybercrime Is on the Rise! Here are examples of potential threats that have been more frequent as of late. »» Financial theft through forged pay requests »» Stolen and locked data for ransom »» Sabotage and brand destruction »» E-mail phishing scams to divert funds »» Impersonation attacks via email If you have questions on any of these topics or concerns, send a request via the Brennan Service Desk at support.jfbrennan.com or email [email protected] with a brief description of your request in the subject line. All standard support requests are processed first in, first out. Depending on the severity and impact on the business and end user, priorities can change. For emergencies, please call Brian, Jeremiah, or Tyler directly.

ENVIRONMENTAL The Grasse River Superfund site is located along the northern boundary of New York state within the ECSlemtanaipntgiruep ethe town of Massena. Arconic Inc. owns and operates an aluminum manufacturing facility that has been around After 12 years, Brennan returns since 1903 and is located within a stone’s throw of the to finish the Grasse River St. Lawrence Seaway. It is the longest continuously operating aluminum manufacturing plant in the world. Nick Collins marking trees for removal Many years ago, when industrial companies commonly used hydraulics that contained polychlorinated Zack Meyers at the controls of the spreader Neenah biphenyls (PCBs), sediment in the river surrounding the plant and several miles downstream came into contact Spreader Neenah placing slope grading fill with PCBs. in the Grasse River Pilot studies were conducted starting in 2001 and involved several years of testing and experimenting with different treatment methods. From this evaluation it was determined that removal and capping of the impacted sediments would be the most effective approach for remediation. Late last year, Brennan was awarded a three-year contract to carry out this remediation using a very sophisticated dredging and capping approach. Since then, we have purchased and developed many pieces of new equipment to carry out this project. In addition to the high-tech tools that we usually bring to remediation projects, we are using several newly developed, specialized tools and techniques. A few of these include: »» In-barge dewatering, off-loading, and sediment treatment techniques that limit land-based processing, storage, and handling of impacted sediment »» Precision mixing of granular activated carbon (GAC) and sand to create an engineered sand cap »» Precision placement of engineered caps, sand covers, and rock armament We are self-performing the majority of the work but are also using some specialized subcontractors such as Putney Tree Service for shoreline vegetation and tree removal, Infrastructure Alternatives, Inc. (IAI) for water pre-treatment, and Perras Companies, Inc. for loadout and trucking. In addition to several Brennan employees, we are employing local union labor from Operating Engineers Local 158. Because this type of work (and equipment) is so specialized, most project superintendents and foreman are also members of the Operating Engineers Local 139 from Wisconsin. Other firms collaborating with Brennan on the Grasse River Project include Arcadis, Anchor QEA, and CDM Smith.

This year, we will remove 80,000 cubic yards of Impacted material being loaded into impacted sediment from nearshore areas and within the sediment processing plant floodplains. We have two mechanical dredge plants focusing on the in-river removal while an amphibious Tim Effland, Tim Whitewater, and Steve excavator is being used in the floodplains. Feenstra spooling wire rope onto a winch We are using a large number of portable barges Andrew Wickman and Jason Johnson to support our equipment and transport dredged decontaminating an excavator bucket sediment to the shore. Six customized sectional hopper barges that hold approximately 100 cubic Jon Walston and Eric Vermeulen changing yards of material each are being used to transport out a material barge sediment from the dredges to a processing and staging area. From here the debris is mechanically removed from the sediment, and then it is dewatered and amended with Portland cement using twin shaftless screw augers. The Portland cement thickens the impacted sediment so it can be temporarily stored and then transported to a designated disposal site. As with most of our environmental projects, once we remove the impacted sediment we have to rebuild the bottom of the river using clean sand or an engineered cap. Following each dredge, we are using our patented Broadcast Capping System (BCS™) to rebuild the river bottom. This year we will place five different types of caps over the dredged areas. We will cover approximately 59 acres with an armored cap, and another 225 acres with a mix of clean sand and topsoil. Environmental projects are always unique. Local interest, adjacent landowners, schedule demands, geographic location, and weather are examples of ever-present challenges. We bring a talented and experienced team of managers, superintendents, foreman, surveyors, and safety professionals who are augmented by several local operators and supporting subcontractors. As we work in new areas and forge new relationships we are often complimented on our culture. We continue to focus on safety, quality and efficiency and executing our work the “Brennan way” to make the Grasse River project a success!

QUALITY a and WITH OVER 100 YEARS OF OPERATION, Im ple m e nBrennan has a distinguished history of providing the highest quality marine construction services. Our clients have great things to say about our people and the exacting specifications to which we work. By Mike Cannell As we continued growing and evolving our capabilities, we began asking questions: »» How can we measure ourselves against our competitors with bigger budgets, more equipment, or a larger geographic reach? »» How do our clients objectively compare our organization with others? »» What specific qualities or services make Brennan the logical choice for prospective customers? »» What one thing, besides cost, influences every client in their choice of contractor? QUALITY IS THE ANSWER! Quality is doing the The consistent execution of contracted services requires right things expertise, efficiency, and safety— which collectively means quality. Outside of cost, quality is the single largest factor in the our clients seek—at times, they look for quality even before right way. examining cost. HOW CAN WE REASURE OUR CLIENTS THAT WE FOCUS ON QUALITY? ISO 9001 is a quality standard developed by the International Organization for Standardization (ISO); that can be applied by any organization in any part of the world. After a company implements the standard and its requirements, the certification process provides an independent and measurable indication that the company established viable and robust quality systems. To become certified, ISO 9001 requires organizations to perform critical tasks, starting with assessing risks to the company and its operations (including people and assets); the organization must also document its objectives. This model for sustained improvement is referred to as the Plan-Do-Check-Act (PDCA) cycle.

and Companies realize some of the PDCA cycle’s most important benefits via the requirement to continually look for and fix relevant issues, making decisions based on facts rather than hunches. Plan—Prepare written plans and processes for managing quality across the entire organization Do—Execute our plan ion Check—Review results internally and externally using ntat outside consultants Act—Identify and address problem areas COMPETITIVE ADVANTAGE Becoming certified under ISO 9001 provides Brennan with a significant advantage. A mere handful of U.S. construction firms hold certification under this standard; Brennan will be the first inland marine contractor to obtain ISO 9001 certification. Achieving any certification is significant, but we understand that we accomplish more compelling benefits through the process of cultivating an effective total quality system. Improved quality drives increased efficiency, communication, safety, and profitability; all this makes Brennan a stronger player in our markets. THE PROCESS AND PROGRESS We have started this process in several areas such as Asset Management, Project Controls, Human Resources, Safety, and Business Development. Each department carefully examined their contributions to every other group, as well as to the company overall. We reviewed, documented, and enhanced our existing processes as needed, laying down lines of communication and responsibility alongside methods to consistently audit ourselves. WHAT’S NEXT? In the next few months we’ll develop foundational processes across our operational groups: the Dive and Environmental Groups will be first, followed by Structural and Civil. We plan to wrap up implementation and training this fall and will meet with an external auditor for certification near the end of the year. While Brennan has targeted ISO 9001 certification as a goal, it is not our only goal. Our true objective remains to conduct business in a way that produces the highest quality results in an efficient manner—project after project and year after year. Obtaining and maintaining our ISO 9001 certification is part of the continuous process of becoming the best version of ourselves. Quality doesn’t come from a project—it comes from a process.

INDUSTRIAL Tapping into their Spyder Sense The Industrial Group uses a state-of-the- art solution to repair a tailrace By Raen Schechinger This past January, the Industrial Group returned to Alliant Energy’s Kilbourn Hydroelectric Dam in the Wisconsin Dells to carry out repairs in the century-old tailraces. For the next three years, our work will focus on walls of the tailrace and steel baffles that help prevent cavitation in the turbines. We began in January, however before we could work on the wall itself, we needed to complete some underwater concrete repairs and replace the sills so we could effectively install bulkheads and dewater the tailrace. As always, we coordinated closely with our client, Alliant Energy, to schedule work during planned turbine outages. This allows them to be able to maximize power production during periods of peak flows in the Wisconsin River. BAFFLE WALLS The first phase of the Killbourn project had a very short window in which we could work. Tailwater elevations from March till May are typically high enough to overtop the bulkheads. This means we only had a couple of months to install the newly fabricated baffle walls once they arrived onsite. Superintendent Troy Kvitek oversaw the first leg of the job, a singular baffle wall replacement. He and his crew did an outstanding job coordinating the work despite having limited area measuring only 30 feet by 25 feet in which to operate. Troy’s team completed the first of three baffle wall replacements this spring and will begin the next one in 2020. Rob Vyvyan (Alliant Project Manager) and Mike Weiers Garrett Mullen & Mike Weiers

REPAIRING TAILRACES Spyder Crane New baffle wall The next step was to complete concrete repairs in one of the tailraces. Access into a tailrace is difficult and we need to use ladders to descend down into a confined area. Once inside, the low ceiling presents a challenge in which we have to constantly be aware of our surroundings to ensure the safety of our crew and the equipment. We monitor water levels continuously and utilize several pumps to manage the water that escapes through the bulkheads. We launched three sectional barges and placed them into the tailrace one section at a time, and then assembled them to make a floating platform. Then, we brought in a small hydraulic crane called a Spydercrane™, which is designed and built specifically to pass through a doorway and work inside of a building. The Spydercrane™ was placed on top of the barges. Its small footprint and low overall height worked perfectly in the tailrace. We avoided having to install an elaborate rigging system using the ceiling of the tailrace because we used this crane. For the largest repair areas, we’re pumping self- consolidating concrete into vertical sections that are roughly five feet tall and 8 inches thick. For shallow repairs, we’re using bagged grout mix. In general, these repairs run from the downstream end of the tailrace to just upstream of the new baffle walls. Additionally, there are planned repairs at the freeze- thaw line on each of the columns between the openings of the tailraces, where we’ll also remove an average of 8 inches of concrete, and continue to install dowels and a reinforcing grid throughout all concrete repairs. Removal and replacement of the bulkhead sills and additional underwater concrete repairs are scheduled to take place when work picks up again this July. CREW MEMBERS INCLUDE: Greg Guck, Mike Weiers, Ryan Marciniak, Garret Mullen, Nicholas Dvorachek, Brian Gerhardt and Project Manager Raen Schechinger. Nick Dvorachek and Ryan Marciniak

Get to know our Accounting Department With the expansion of our Accounting Department and some other internal changes we’d like to re-introduce our team. This is a brief overview of our staff and their responsibilities. Tina Klinger Wibralski | CFO Tina Skau | Controller Directly oversees I.T., Accounting In charge of the Brennan and Business Analysists. She Accounting Department and has many other corporate level oversees the production responsibilities. She is the main of financial reporting. contact to review contracts for Any questions regarding legal and insurance issues. accounting reports, job cost related reports, and any other accounting issues related to Brennan should be directed to Tina. Joyce Brueggeman | Accounting ManageR Beth Troke| Payroll Supervisor Oversees Brennan Marine Responsible for reviewing union (BMI) financials. Any questions contracts to make sure all union regarding reports, BMI employees are making prevailing equipment, account coding and wage within each district we have other accounting issues related been awarded a project. She also is to BMI should be directed to the contact person when unions and Joyce. business agents have any questions or concerns regarding wages and fringes. She’s available to provide support to traveling employees entering and approving timecards in HeavyJob. She processes salaried bi-weekly payroll and weekly subsistence. She oversees all aspects related to payroll. Jim Dahl| Payroll Coordinator Eric Steffes | Accounts Payable Supervisor Responsible for processing Oversees all aspects weekly payroll. He’s available to related to accounts payable. provide support to any employee Responsible for vendor questions as it relates to payroll. and internal staff inquiries regarding status of payments. Coordinates the processing of all invoices for payment. Reviews all invoices for appropriate expense categories and sales/use tax compliant.

Tony Thorsen |Accounts Payable Specialist Toni Wuttke| Accounts Payable Specialist Responsible for oversight of Responsible for routing and corporate credit card reporting coding invoices within eCMS and receipt processing in Content Management. Also Expense Track and assisting any assists with processing new staff members with questions supplier credit applications. or concerns. Additional responsibilities include processing new supplier credit applications and routing and coding invoices within eCMS Content Management. Kari Brown| Accounting Specialist Dan Wisniewski| Accounting Specialist Responsible for unit price Responsible for time lump-sum contract job setup, and material (T&M) and preparation and submittal of miscellaneous jobs setup, contract invoices, requests preparation and submittal of insurance certificates for T&M invoices (except Dive), contract-related projects, requests insurance certificates reviewing and submitting for T&M projects, preparing subcontract certified payrolls, and submitting internal certified eSRS small business reporting, payrolls, preparation and vendor portal financial setup, distribution of weekly accounts entering and payment approval/ receivable and job cost reports tracking of subcontract invoices and assists with State DOT and annual State DOT reporting. annual reporting. Ashley Sebo| Equipment Accounting Specialist Responsible for equipment setup in accounting, monthly cost review for work in progress and equipment capitalization, weekly processing of equipment in HeavyJob, weekly compiling of YTD equipment usage, analysis, compiling equipment- related graphs and requests insurance certificates related all J.F. Brennan Company equipment. Ashley’s time is split between Asset Management and Accounting.

STRUCTURAL GROUP Lock and Dam 20 Gate Machinery & Anchor ages By Wyatt Eaton The last time the drive units, bearings, shafts, couplings, and shaft keys were replaced, was during a major rehab in the late This year, our team completed 1980s. For this portion of the project, we coordinated with three work on a project we were awarded subcontractors and over a dozen suppliers to cut concrete, nearly two years ago with the U.S. perform electrical work, and supply the equipment necessary Army Corps of Engineers (USACE) to renew the operating machinery. – Rock Island District. The work included overhauling and replacing We also replaced 84-year-old miter gate anchorages. These pieces of machinery that operate miter gate anchorages essentially anchor the gate that allows the lock, as well as demolish and vessel traffic in and out of the lock chamber of the dam. They replace the concrete in and around are heavily embedded into the lock wall and are surrounded by the miter gate machinery recesses. many tons of steel and concrete. To remove these anchorages, we had to cut them out of the lock wall, along with a substantial amount of concrete. Four of the six anchorages had to be removed via the “grave method.” We coined the term “grave method” during the Lock 11 Major Rehab Project back in 2006. It refers to a process that requires various configurations of wire and pulleys to cut concrete blocks out of the middle of a lock wall. In total, we removed six anchorages and 12 30,000-pound concrete blocks from the dam. The new LR1300 hard at work.

Removing miter gate machinery support platform Brian Schulte and Paul Lamb sending off a concrete block Finished sector and pinion gear assembly In a way, Lock 20 was the “test dummy” for these new Shulte, Project Manager Wyatt Eaton, and Foremen anchorages. Prior to fabrication, the new anchorages Dave Bahl, Brian Schulte and Jim Balonis, our crews required design changes. Working closely with the logged over 15,000 hours without a lost time incident in USACE and our fabricator – Awerkamp Machine - we some extreme conditions. were able to accommodate the changes. The USACE was determined to gather as much engineering data We encountered many challenges throughout the as they could to perfect the new anchorage design project. The main challenge was the mixture of cold for future use. We provided land and marine support and warm temperatures. Cold temperatures prevented to the U.S. Army Research and Development Center us from getting concrete delivered from the ready-mix (ERDC) while they performed load tests and collected plant. The plant wouldn’t deliver on weekends, or when data after the anchorages were installed. The data temperatures dropped below 20°F. This made it difficult would ultimately be used to analyze stresses in the new to meet our required cure times, which were critical anchorages during operation of the miter gates. in keeping on schedule. As temperatures fluctuated from one extreme to the other, ice formed, and we We also installed a new traveling kevel, replaced were faced with major ice jams upstream. This made it tow haulage units, and completed lock wall concrete difficult to pull the lock chamber bulkheads at the end and electrical duct bank repairs. Two marine plants, of the project. multiple material barges, air compressors, and welders were required to provide support to the upstream and Despite the unique conditions and difficulty of Lock 20, downstream crews. We performed most of the work our safety, professionalism, and quality of work did not under the roof of 12 separate insulated shelters, a go unnoticed. The USACE was very pleased with our potential record for our lock projects! performance and intends to give us “exceptional ratings,” which is very rare, on our Contractor Performance Construction was accomplished during the 2018- Assessment Reporting System (CPARS) evaluation at 19 winter navigation closure, a period of 11.5 weeks. the end of the project. We worked 70 hours per week for the duration of the project. Under the leadership of Superintendent Travis Dave Bahl shooting elevation on a miter gate anchorage Ice jam upstream of the bulkheads Kevin Miller and Dave Bahl leveling/aligning a miter gate anchorage

ASSET MANAGEMENT Brennan Abroad: Asset Management Goes to Munich BAUMA IS THE LARGEST CONSTRUCTION TRADESHOW IN THE WORLD. It is held every three years in Munich, Germany, where 620,000 people from over 200 countries spend 7 days learning about the latest and greatest equipment on the market. Nearly every international manufacturer can be found as one of the 3,700 exhibitors who showcase everything from o-rings to giant mining machines. The last show took place from April 8th-14th and three people from Brennan had the opportunity to attend. Director of Asset Management Paul Berendes was invited to Munich on behalf of Liebherr North America and American State Equipment (ASE). We own several pieces of Liebherr equipment, and ASE is our primary distributor for sales, parts, and service. Vice President of Asset Management Ken Peterson and Chairman Tony Binsfeld also flew to Munich to attend the show. We recently took the opportunity to ask them about their trip. Germany is a long way away, why is it important that we attend Bauma? K en: Attending Bauma is about seeing how things are done by others outside of the United States. Brennan, same as all large contractors, is buying equipment from outside the United States. The construction equipment market is truly global. Quite a few of Brennan’s largest assets are manufactured in Germany. The days are filled with walking the trade show, attending pre-set meetings with our current vendors, creating new contacts and seeing equipment that has the potential of creating efficiencies for Brennan.The meetings give us the chance to meet people face-to-face that we would not normally interact with, such as support staff, engineering, technical staff, and executives. What else did you experience while abroad? Paul: Since I was invited on behalf of Liebherr, I got the opportunity to spend my first few days traveling the countryside of Germany and Austria visiting different Liebherr distribution centers and manufacturing facilities. In Austria, I visited the Liebherr Parts Distribution & Logistics Center and the Material Handler & Wheeled Excavator Plant, both in Kirchdorf, the Dozer Manufacturing Plant in Telfs, and the Wheel Loader Manufacturing Plant, in Bischofshofen. I traveled from location to location with various representatives from Liebherr, ASE and other construction companies. There were endless business networking opportunities and resources to answer all questions regarding Liebherr. We spent the last two days of our trip attending the Bauma 2019 construction and equipment expo. It is multiple times larger than its North American counterpart– CONEXPO. There were thousands of exhibitors from throughout the world and I had the opportunity to experience some of the biggest pieces of construction equipment manufactured, along with all the newest technology and cutting-edge ideas.

What else did you experience while abroad? K en: Beyond the trade show, Tony and I toured the Sennebogen Manufacturing Facility and Sennebogen Museum in Straubing, Germany. Sennebogen is a machine building company with around 1,600 employees and is structured similarly to Brennan. It’s a family-owned company in its third generation, beginning back in the 1950s. A day after touring, we were invited to a dinner, neither Tony nor I thought the evening would be as impactful as it was. We were seated with the owners of Sennebogen, brothers Erich and Walter, Erich’s son Anton, and the President of Sennebogen – US Constantino Lannes. The evening was filled with talk of how Sennebogen and Brennan could work together for the benefit of both companies. Is there a difference between the way things are done in Europe versus the U.S.? Paul: One take away I was in particularly impressed with, was the European take on manufacturing. The people working in their factories seemed to take a pride in their work that I hadn’t seen in any of my previous U.S. factory tours. These factories were not located in areas traditionally associated with manufacturing. Instead of being in industrialized areas as we would traditionally expect, they were primarily located on the outskirts of smaller towns at the foothills of the Alps. K en: There’s a difference in working environment and how they move equipment around. The transportation equipment is much smaller, lighter loads, the equipment itself is smaller, and is made to work in more compact working environments. Automation was a big theme in this year’s Bauma. Robots were assisting in many more applications than in previous years. Paul Berendes with the American State Equipment group Drone photo of outdoor showcase Liebherr displays at Bauma 2019 What was most beneficial about your trip? Paul: The most beneficial part of the trip had to be the opportunity to travel with so many resources from Liebherr and ASE while touring various facilities. We have have a long-standing relationship with Liebherr and some hiccups along the way. But, being able to see facilities firsthand and talk directly with many folks involved with both companies was invaluable. I think we were able to clear up many questions and concerns, and I was able to gain insight into the direction each company is headed. I was very impressed with how all the manufacturing and distribution is handled in Europe and am hopeful that many of these practices are implemented in the North American market. K en: The scale of Bauma is immense. It always gives me insight to new concepts, equipment, and the opportunity to further improve on the Brennan fleet of equipment. This year was no different. Great connections made and meetings with Hyundai, Sennebogen, Cat, Liebherr, Mantis – Tadano, Link Belt, Manitowoc, Bigge Crane, and many more. We had some impromptu meetings as well. One such meeting was with Bell Dredging Company. Bell manufactures their own amphibious undercarriages, excavator dredge pumps, and many more items that we are pursuing currently. BAUMA 2019

DIVE When the Tool Doesn’t Exist, Taconite iron ore strip mine in Minnesota WE INVENT IT By Dave Schlenker THE DIVE GROUP SOLVES A DECADES-OLD PROBLEM Iron ore is a commodity generally found in northern Minnesota and is used to make steel. Before leaving the Iron Range, the ore is turned into taconite pellets by mines and plants centered near Duluth, MN, then is distributed via train or freighters from the port. The process of making taconite pellets requires a steady flow of water, in this area it’s primarily sourced from the St. Louis River. Sand, silt, and debris from the river can make its way in through an iron ore processing plant’s intake and settle in the water storage tanks. Over time, the material builds up at the bottom of the tanks and lowers their capacity to hold water and increases the weightload on the system. In October of 2018, a taconite mining and processing plant contacted our Duluth office to inquire about cleaning out 54 years of settlement from its tanks. As it turns out, several attempts have been made over the years to clean these tanks, resulting in unplanned shut downs because the sediment would get resuspended and make its way into the cooling water. They needed a new strategy and a contractor with fresh ideas. Cleaning out water storage tanks is not a big deal. We do it all the time. However, this project was different. Regional Dive Manager Dave Schlenker visited the site and discovered that there was one major challenge to this project. The plant could not shut down while the tanks were being cleaned. The cooling system had to remain online the entire time, which meant that divers could not enter the tanks safely. Taconite pellets Orie Anderson, Jeff Patrouski and Tony Domek

CHALLENGE ACCEPTED! Our innovative open suction dredge head Of course, Dave and the Dive Group are not ones to back down from a challenge. Before long, they had put a plan together that could clean the tanks and keep divers out of harm’s way. Their solution was to design a custom hydraulic diverless-dredge system that could be controlled from above the tank. The system was simple, yet ingenious. It consisted of a small open suction dredge head mounted on the end of a pole. A flexible hose was then connected to an electric submersible pump which created the suction necessary to suck the sediment up from the bottom of the tank. A vacuum brake in the pipeline became critical in making sure that the hose did not collapse when it got clogged with debris. After proving that this tool was effective, they added another person to the crew and were able to double their production by assembling another dredge system. The crews had to work above the tanks, which meant they were working 65 feet above the floor of the plant. They used beam clamps with independent fall arrestors and scaffold planks to work safely. The crew’s underwater rigging skills came in handy as well. Portable winches and rigging were necessary and there wasn’t much room to assemble the equipment and rig the pipeline. For individuals who are used to working in confined spaces, this feature of work was second nature to them. NOT EASY, BUT VERY EFFECTIVE Crew members controlling the dredge head Cleaning the tank was quite challenging and took a lot of effort. from above the tank Standing 10-13 feet above the dredge head the operator had to muscle the pole around the tank to reach the settled material Jeff Petrouski and Tony Domek embedded between all the piping and fittings that are found in tanks like these. At times, the lines and pumps were easily plugged by debris and became hard to handle. Supervisor Pat Rude put it best, “Holding onto the pole and hose was like wrestling an anaconda!” In total, 460 cubic yards of material were removed from the tanks in 5 weeks. This sounds small by comparison to a typical Brennan dredging project, however every yard was a challenge. Most importantly, it solved a problem that our client had dealt with for over half of a century! At the end of the project they were very impressed and approached us with another opportunity to dredge a retention pond. The plant Safety Manager stated that our crew did a great job, especially on the safety aspect of the project. The taconite plant’s main tank cleanup completed in May. Supervisor Pat Rude, Jeff Petrouski, Tony Domek, Paul Hovanga, Shane Monahan, Orie Anderson and Joe Baldoni were all involved in the project. A big thank you to the Brennan Safety Department for their guidance and help with the rigging and fall prevention equipment!

Highlighting Innovation: Introducing the WSE Buoy Submitted by Josh Podjaski and Dan McCauley

Last year, J.F. Brennan Company leased an AXYS Wave we needed we had to invent our own custom system. The Buoy (AXYS) to monitor conditions at the mouth of the Fox survey team, along with the help of some of the Fox River River in Green Bay, WI. Wave buoys enable us to measure operators, built a buoy and support raft out of spare parts and monitor wave height to ensure safe vessel operations that were found around the job site. We added a GPS on the water. On the Fox River Dredging Project, we receiver, buoy lights, and two GPS transponders that we can compare wave height at the mouth of the river to the height use to find the buoy if it were to break loose and drift away. at the Dredge Mark Anthony located 1,000 feet out from the mouth. We also changed how the buoy transmitted its data. The newly “Brennanized” buoy sends data via wireless radio The plan for the AXYS buoy was to collect wave height (rather than cell link) to the dredge. Working closely with the information and transfer all data to a cloud-based program company that creates our dredging software, we were able so it is available to multiple people in real-time. We were to display the information right on the dredge monitor in front hoping that everything would work smoothly, but we ran into of the leverman. This new software allows us to customize problems. There was a long delay between data uploads, the rate at which the data is displayed, plus it allows us to plus the quality of data we were receiving was subpar. We set an alarm to alert the operator when the average wave could have used this buoy to collect sampling data or gauge height hits a specified limit. tides themselves, but we couldn’t use this data the way we needed it – to measure the differential in surface elevation So far the new system is a success, and after more sea at the dredge versus the mouth of the river. trials we plan to make a new version that is more robust and uses better equipment. This system, dubbed the Dan McCauley spoke with fellow surveyors and project Water Surface Elevation (WSE) Buoy, will be very useful in engineers to weigh the pros and cons of the situation. monitoring wave actuation and help us stay safe out on the Before long, he concluded that in order to get the data open water.

RAILROAD Jeremy Kroll laying out pile locations The Rail Group EXPANDS its Capabilities One of our best railroad clients was having some issues with one of their tracks misaligning as it transitioned off of a bridge in Milwaukee, WI. They needed a unique solution and reached out to our team to assess the situation and help determine a plan of action. AFTER INSPECTION, we determined that an abutment, which supports one end of the bridge, had settled because the underlying soil was not stable. To properly resolve this issue we suggested that helical piles would be a great application for this problem. For our client, helical piles were a perfect solution. We proposed that we essentially create a new, deeper foundation for the railroad track and use helical piles to “pin” the existing abutment and foundation to it. Upon approval, we went to work!

Brennan;s new helical drivehead Starting helical installation Jeremy Kroll and Cole Kamla I’VE BEEN WORKING ON THE RAILROAD, In addition, we dug out a section of loose fill from ALL THE LIVE LONG NIGHT under the approach and pumped flowable fill back into In April, six crew members began work on the bridge. the void. We also did some other miscellaneous work Nighttime train schedules are typically slower, so we like installed retainer rods to anchor the approach span had to work at night. We also had to work around to the abutment and prevent any movement between schedule changes. For instance, if there was a the two. train scheduled at 12am, work would have to be rescheduled to accommodate. This was the first time our team had installed helical piles with a high rail excavator, and we were surprised We built and underpinned the new addition on the river at how quickly we could install them. Each section was side of the existing abutment. To do this, we cleared 18 feet in length and would only take about 7 minutes debris and dug back the embankment in front of the to drill into place. Another section would then be bolted old abutment. We then screwed 10 helical piles ranging onto the previous 18-foot section and the 7-minute in length from 72 feet to 108 feet at either 20-degree drilling process would begin again until their lengths or 30-degree angles off of vertical using our high rail reach 72 feet or 108 feet. excavator. Dowels were then drilled into the existing abutment and square steel plates were welded to the Dennis Jonjak, Jeremy Kroll, Eric Boldt, Cole Kamla, tops of the helical anchors. All were tied together using and Quentin Thorson were all involved in this project. rebar. Once in place, the new foundation was formed up and we poured concrete using a slick line. When completed, the new foundation added strength to the original structure, which was supported on wood piling. What are Helical Piles? Referred to as screw piles, helical piers, or screw anchors – helical piles are hollow steel tubes that are used to stabilize structures by transferring loads to the surrounding ground, much like a driven pile. However, this type of pile gets “screwed” into the surrounding soils and its bearing capacity is a function of the amount of torque applied during installation. They especially come in handy when there is structural damage to a foundation or in our case, a bridge abutment. This type of repair is called “underpinning” and does not require the use of an impact or vibratory hammer. The length of the piling is adjustable which makes them very economical. To reach greater depths we just add more sections as we go.

Dredger President and CEO Matt Binsfeld brought home the 2019 Dredger of the Year Award on Thursday, June 6th, while at the Dredging Summit and Expo of the Year in Chicago, IL. The Western Dredging Association (WEDA) selects one person annually who has made outstanding contributions to the dredging community as well as the WEDA organization. We're honored to have Matt as our leader, and we're very proud of our Brennan team. As Matt mentioned in his acceptance speech, without the hard work and dedication of everyone on our team, this wouldn't have been possible. “I am truly honored to receive this award. The Western Dredging Association is an important group for the advancement of the dredge industry in the United States, North and South America. To be recognized amongst your peers is always nice; however, I find it more so an opportunity for reflection. I have been truly blessed to have some wonderful mentors in my career, the only way I can repay them, is to pay it forward. Most of all I want everyone to know that this is an award for all of Brennan. There is not a day that goes by, where I don’t think about how lucky and fortunate I am to work with so many awesome and dedicated people. Our work has great purpose and we are making a positive impact in this country because of our great team and high-quality work.” – Matt Binsfeld Thank you to everyone at J.F. Brennan Company for being a part of our team and for making our company worthy of this wonderful award! Congr atulations Matt Hogan! The Inland Marine Expo (IMX) took place May 20-22nd in St. Louis, MO. Engineers, suppliers, contractors, buyers, marine professionals and government officials from around the country were in attendance. On the last day of the conference, publisher Nelson Spencer Jr. of The Waterways Journal presented the 40 Under 40 Awards to a small group of marine professionals. Our very own Matt Hogan was selected this year and went on stage to receive his award in front of the IMX audience. WHAT ARE THE 40 UNDER 40 AWARDS? The 40 Under 40 Awards feature “men and women under the age of 40 who have made significant contributions to the inland marine transportation industry and collectively promise to play a big role in shaping its future.” Nominated by their peers and voted on by The Waterways Journal, this group of forty individuals was introduced and celebrated on National Maritime Day. WHO IS 40 UNDER 40 WINNER MATT HOGAN? Matt has worked with J.F. Brennan Company since 2014. He has since become our representative for much of the work we do on the Illinois River and lower portion of the Upper Mississippi River. He has overseen several multi-million-dollar projects that include Lock and Dam repair work and barge terminal construction. Before coming to Brennan, Matt worked for Walsh Construction and was involved on large lock and dam construction projects on the Ohio River. Matt has been an integral part of the Brennan team. He has been a go-to resource for our clients along the Illinois River as he goes over and beyond to understand their needs. He personifies our culture at Brennan through his hard work, honesty, integrity, focus on safety, and the respect he shows those with whom he works. Matt has a bright future here at Brennan and in the river industry and is very deserving of the IMX 40 Under 40 award. Congratulations Matt and thank you for all you do!

Introducing a New Structure for the HR Department Brennan’s success continues in geographic expansion and closely partnered relationship with each department, employee, corresponding employee growth. The Human Resources (HR) and manager. Our new structure will allow us to provide: department, which provides services such as recruitment, compensation support, performance management, employee »» A dedicated HR resource focused on every operational and relations, and employee engagement, has been traditionally administrative group structured with specialist employees who focused on those individual areas. But as we grow, we need to reorganize HR to »» A stronger pulse on the unique needs of each employee and respond to the demographics of our workforce and employee department development opportunities so that we keep making Brennan a great place to work. »» Increased coaching and management engagement Beginning on July 1, we will provide an HR Business Partner for »» Cross-training within the HR department for succession and each Group/Department. Each HR Business Partner will serve contingency planning as a “one-stop shop” for nearly all HR services, including hiring, compensation support, communication, employee relations, We have already started rolling out this process and plan to employee engagement, performance management, policy and formally transition to our new structure in July. program development, and learning and development. We are excited to restructure the HR department to allow us to The growth of our organization requires us to have a more partner with every group and better enhance each employee’s career and employment experience. Please keep providing us with input and feedback on how we can continue to make Brennan a great workplace. HR Business Partners will be assigned as follows: Angela Wierzbicki Bob Brague »» Civil »» Rail »» Directors and VPs »» Lock and Dam »» Oversight of HR Business Partners Kristi Umberger Wendy Shepard »» Accounting/IT »» BMI (La Crosse, Lansing, »» Environmental Ste. Genevieve, Paducah) (East Coast) »» Dive and Industrial »» Estimating (Underwater Services) Becky Hughes Becky Hughes , SHRM-SCP joined the Brennan team on May 28, 2019 as our newest HR Business Partner. She will partner with Asset »» Asset Management Management, Safety, Business Development and a portion of the »» Business Development Environmental group. Becky is a UW-La Crosse grad and has over »» Environmental (Midwest) 15 years of HR management experience at a variety of organizations, »» Safety including Gundersen Health System, Organic Valley, and Dynamic Lifecycle Innovations. She has two daughters who are in 5th and 8th grade and spends most of her free time running them to dance, softball, basketball, show choir, and various activities. Born and raised in Rochester, Becky is a Minnesota girl at heart and proud fan of the MN Vikings. Becky is also married to a local musician and although she doesn’t play any instruments (besides attempting to learn the bass guitar), she loves being involved in the music scene when she’s not outdoors enjoying hiking trails or cruising on the river.

MILESTONES & DATES TO REMEMBER Years of Service Anniversaries 5 Years 10 Years JOSHUA CONNAUGHTY 03/24/2009 BRETT DVORACHEK 03/20/2014 CADE ELLIOTT 04/10/2009 JOSHUA MARTZAHL 04/14/2009 SAMUEL MARSHALL 03/31/2014 DAVID SPERBERG 04/20/2009 BRAD DVORACHEK 04/21/2009 KRISTI UMBERGER 03/31/2014 ERIC STEFFES 06/08/2009 NATE PINKLEY 06/30/2014 SCOTT KRALL 04/18/2014 CHRISTOPHER PETTY 06/30/2014 TODD BIERK 06/30/2014 JONATHAN ANDING 04/21/2014\\ DANIEL GANTER 04/21/2014 BRAD TENOR 04/21/2014 JOSEPH FRANCKSEN 05/12/2014 TRAVIS KICKHAVER 05/19/2014 JACOB KRUCK 05/20/2014 30 Years VICTOR BUHR STACY BEAN 06/09/2014 KEN PETERSON 04/24/1989 06/01/1989 STEVEN SKAU 06/09/2014 40 Years CRAIG BARTHELD 06/18/1979 MATTHEW HOGAN 06/30/2014 Great Place to Work Launch: June 24th The Great Place to Work organization requires that over 70% of employees state that an organization is a great workplace in order to gain certification. If Brennan meets this threshold, we will be re-certified for 2019-2020. After receiving this anonymous feedback, Brennan’s Great Place to Work Task Force will analyze the data and brainstorm solutions to make Brennan a better place to work. Surveys will be administered to employees via Brennan or personal e-mail. There will also be a global link that can shared via e-mail or even text and will be posted on the intranet and shared on job-sites. The 2019 survey window will be June 24th-July 8th. All responses are completely anonymous. Mark your Calendar! JULY 4, 2019 - THURSDAY Office Closed for Independence Day JULY 13, 2019 - SATURDAY Family Night at the La Crosse Speedway AUGUST 9, 2019 Retiree Celebration at La Crosse Office MARCH 21, 2020 Brennan Annual Celebration at the La Crosse Center

JOSEPH GOUTERMOUT 03/11/2019 OPERATOR 03/25/2019 CARPENTER KURT LEHMKUHL 04/01/2019 MECHANIC 04/01/2019 OPERATOR TIMOTHY EFFLAND 04/01/2019 CONTENT MARKETING New 04/03/2019 SUPERINTENDENT Hires CALEN MCNALLY 04/08/2019 DECKHAND 04/08/2019 SITE SAFETY MANAGER KIM WALTERS 04/08/2019 PROJECT COORDINATOR 04/09/2019 OPERATOR QUENTIN THORSON 04/09/2019 OPERATOR 04/09/2019 OPERATOR CONNOR FALING 04/09/2019 OPERATOR 04/09/2019 OPERATOR STEVEN LINBERG 04/10/2019 OPERATOR 04/10/2019 OPERATOR JULIE SHARLOW 04/10/2019 OPERATOR 04/10/2019 OPERATOR JOSEPH CONKLIN 04/10/2019 OPERATOR 04/10/2019 OPERATOR DONALD EDWARDS 04/15/2019 SENIOR PROJECT MANAGER 04/15/2019 DIVER RONALD GOODFRIEND 04/18/2019 DIVER 04/19/2019 OPERATOR RUSSELL HATHAWAY 04/24/2019 OPERATOR 04/29/2019 OPERATOR JASON JOHNSON 04/29/2019 LABORER 04/29/2019 CARPENTER TIMOTHY DERR 04/29/2019 DIVE MAINTENANCE 04/29/2019 DIVER WILLIAM MCBROOM 04/29/2019 DIVER 05/03/2019 OPERATOR CHAD THARRETT 05/07/2019 INTERN 05/07/2019 SUPERINTENDENT ALLEN TUPPER 05/07/2019 INTERN 05/13/2019 OPERATOR JAMIEE WHITFORD 05/14/2019 INTERN 05/14/2019 INTERN STEVEN WILBER 05/20/2019 CARPENTER 05/20/2019 OPERATOR DAVID HORNE 05/21/2019 INTERN 05/21/2019 INTERN SHADI ODEH 05/21/2019 INTERN 05/22/2019 OPERATOR ASHLEY HIGGINS 05/22/2019 INTERN 05/22/2019 LABORER THOMAS CROSSMON 05/23/2019 DECKHAND - THREE RIVERS 05/23/2019 LABORER JONATHAN CAPONE 05/28/2019 INTERN 05/28/2019 HR Business Partner BLAKE CRENSHAW 05/28/2019 OPERATOR 05/28/2019 PILOT JOSHUA MAGNER 05/29/2019 INTERN 05/29/2019 PROJECT ENGINEER I MICHAEL MCGLASSON 05/29/2019 ESTIMATOR BRYAN MEHUS MAXWELL ROOZEN SEAN TREMBLAY MARK VANPATTEN NOAH AGATA RODERICK EYRES NOAH KOBALL CODY BISHOP RYAN OSHEA ZACHARY SERVINSKI CHAD DAVIDSMEYER JOSEPH SLEDD SAMUEL BAUMAN JOSEPH VELLA KEVIN WISKOW JUSTIN BAYER CHARLES HLAVACKA MICHAEL JESSEN STEVEN NOLES CHASE SMITH ISAAC BYRD REBECCA HUGHES RUSSELL JOHNSON LAWRENCE RICHARDSON MYLES MALONE JACKSON RADENZ DANIEL SAVOY

2019 Golf June 8, 2019

MEET THE 2019 INTERNS! At Brennan, we value growth and development. Our internship program strives to provide students with practical experience and useful knowledge to sharpen their skills in their chosen field. Interns follow our COMPASS program where they will gain real-world experience to help prepare them for promising careers. Noah Agata Sam Bauman Josh Gruen Calob Limberg Environmental Intern Lock & Dam Intern Environmental Intern Lock & Dam Intern Michigan Tech UW-Platteville UW-Platteville UW-Madison Kaitlin Brown Charles Hlavack Isaac Byrd James Lydon Safety Intern Estimating Intern Environmental Intern Lock and Dam Intern Mass Maritime Academy UW- La Crosse University of Missouri Iowa State Ian Radcliffe Joe Vella Kevin Wiskow Myles Malone Industrial Intern Environmental Co-op Environmental Intern Environmental Intern University of MN-Duluth Iowa State UW- Platteville UW- Platteville Noah Koball Ryan O’Shea Tyler Henson Zach Servinski Jake Taylor Environmental Intern Dive Intern Mechanic Intern Environmental Intern Accounting Intern Michigan Tech Michigan State Air Force Michigan Tech UW- La Crosse

Cour age, Confidence, and Good Sense Steve Becker Wraps up His 45-Year Career on the River Steve Becker has finished a long and storied career a full-time career as a crew member in Robers’ dredge covering just about every nook and cranny of the division. For several years, he worked in various Upper Mississippi River. For most of his time at locations along the Upper Mississippi and Missouri Brennan, he stood at the helm of the Lock and Dam Rivers, including the Gateway Access project where Division, which later evolved into the Structural Group. they built roads through the marsh in La Crosse. He orchestrated the growth that made Brennan the most dominant Lock and Dam contractor on the Upper By 1989, Steve wore many hats at Robers while Mississippi River. working long hours. That year, he led a job digging the marina in Trempealeau, WI. During the week, he did Steve began his career at Kertzman Dredging in everything from pulling levers on the dredge to running 1974, working for his father Duane. He was still in high a dozer and surveying. Brennan and Robers were school at the time, but helped crews assemble dredge teaming up to pursue levee restoration work by that tows and performed miscellaneous yard work at their time; one of these joint efforts was near Lock and Dam Lamoille, MN yard. He worked up to about the time that 21. So on weekends, Steve drove down to Quincy, IL to F.J. Robers Company (Robers) bought out Kertzman do maintenance on two dredges there. in 1977, and then entered the University of Minnesota to pursue a Mechanical Engineering degree. During Brennan bought out Robers’ dredge operations in summers, Steve returned to Robers to work. One of his 1990; Steve and several other individuals joined the projects included dredging the Cowlitz River in 1980 Brennan team and became involved in Brennan’s first after Mount St. Helens erupted! hydraulic dredging projects. In 1992, Steve began working with Pat Vickman, our first Lock and Dam After graduation in 1982, the pull of river life drew Division Manager. At this point, Steve worked as Steve back to the La Crosse, WI area where he began the Quality Control (QC) Manager for a machinery

replacement project at Lock and Dam 15. By 1994, he 2014 Patent Awards for Innovations at the Lock and Dam 11 was spending most of his time working on Lock and Dam Rehab Project - Dan Wibralski, Steve Becker & Jeff Steiber projects as a QC Manager. 2001 Steve Becker at his desk in the old office In 1999, Steve officially became Brennan’s Lock and Dam Division Manager when Pat decided to return to the U.S. 2003 Lock 15 Tainter Gate Machinery Replacement Army Corps of Engineers to finish his career. Steve’s transition to this position was a challenge as Brennan 1992 Lock and Dam 15 Miter Gate Project had just landed the Lock and Dam 14 Stage 2 Major Rehabilitation project. There was a steep learning curve, but Steve’s hard work and a seasoned crew made for a successful job. Those of us who had the opportunity to work with Steve will long remember his tenacity and drive. He’s never one to back down from a challenge, even when it means taking on new scopes of work or penetrating unfamiliar geographic markets. During his two decades of leadership, the Lock and Dam Division evolved into a reckoning force along the Upper Mississippi River. Competitors who once dominated lock work along the river have all but disappeared as Brennan grew in knowledge and ability. Steve always had a willingness to expand off the Mississippi River. For years, he worked with Dave Cullum and the Specialty Division—now called the Industrial Group—to pursue projects on area hydroelectric dams for utility companies and paper mills. Together, Steve and Dave laid our foundation for being one of the only contractors in the country who can self-perform both above- and below-water work. In 2004, the newly formed Specialty team performed concrete repairs at Alliant Energy’s Prairie du Sac hydroelectric dam; this started a solid, valuable partnership that is still going strong after 15 years in the Structural Group. As Steve hangs up his hard hat one last time, we recall one of his greatest legacies: a Structural Group that is well-positioned for growth and success. Steve slowly and unselfishly handed over the reins of the Structural Group to the strong leadership of Jeff Steiber and Dan Wibralski. After many years of working together, Brennan has a confident and experienced team that will undoubtedly build on the success that Steve found over the course of his career. Reflecting on his 45-year career, Steve had this to say: “To me, I have always worked at one company. I started with Kertzman, which was bought by Robers, which was bought by Brennan. I’ve had a pretty good run.” Steve went on to leave a piece of advice which sums up the way he approached his work, “You can’t be afraid to challenge work in areas that have been dominated by somebody else. You just can’t be intimidated. That’s where self-confidence comes in. You can’t feel like your inferior to anyone. That’s important. But, you do have to have a good sense of what you can and can’t do.” Thank you, Steve, for being such a big part of Brennan. Congratulations on your retirement!

Search

Read the Text Version

- 1 - 40

Pages: