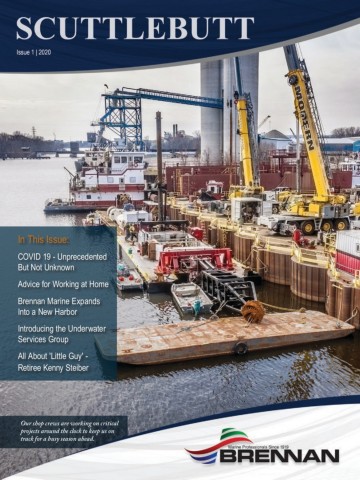

In This Issue: COVID 19 - Unprecedented But Not Unknown Advice for Working at Home Brennan Marine Expands Into a New Harbor Introducing the Underwater Services Group All About 'Little Guy' - Retiree Kenny Steiber Our shop crews are working on critical projects around the clock to keep us on track for a busy season ahead.

Unprecedented but Not Unknown We Must be Smart, but We Will Get Through This… There is really only one topic to cover in this a baseline, we take our cues from the Centers edition’s cover article. The outbreak of COVID-19 for Disease Control and Prevention (CDC) and has created an unprecedented crisis in our country Occupational Safety and Health Administration and around the world. None of us are accustomed (OSHA) as they publish their guidelines. We are in to the speed with which the situation is developing, uncharted territory, so every idea is considered or our growing understanding of the latest a good idea and we want to err on the side of information and how it changes. Throughout this overcommunication with those in our Brennan edition of the Scuttlebutt, you will read of the many family. Every action we take is guided first by what specific actions we are taking as a company to keep is safest for our people and second by making sure people safe. The Brennan Leadership team meets that people can go to work without disruption to daily to review the latest information and apply their weekly compensation. it, implementing best practices throughout our company. We are analyzing and planning for every The COVID-19 outbreak and crisis are conceivable scenario as this “black swan” event unprecedented, but not unknown in many respects. unfolds. Global pandemics occurred with various strains of influenza in 1918, 1957, 1968, and 2009. Further, Each day, we speak with our many partners, clients, we cannot forget HIV/AIDS, which peaked globally and related businesses and industry organizations in 2005. We have also known numerous times of to understand their circumstances. In all cases, we shared national sacrifice. When seeing the noble seek to confirm that our practices are in alignment actions of health care workers, flight attendants, with or above generally accepted standards. As mass transit workers, and others who conduct their

work among large crowds or with sick patients, you country, we will learn to protect ourselves while can’t help thinking of other instances where our living with this contagion, so that to the extent nation has risen to address difficult challenges. possible, essential and important work in our One’s mind quickly goes to the concerted war effort economy may continue. Just as there is dignity in of the 1940s and the tremendous work during the the work performed by many of our fellow citizens five decades of the Cold War and 9/11. In all cases— during this crisis, there is nobility in our work as outbreaks or existential threats to our country—we well. What we do is critical to the long-term well- come together, we survive, and we go on to thrive being of this country. Our jobs at Brennan are as a country. The same will happen when we defeat important to both our families and our economy. As COVID-19. we move into April and fully know that we have the best practices in place to keep people safe, we will No one knows what the path forward holds as we conduct our work in the industries deemed essential work together to contain the outbreak, heal our sick, by the President and our States’ Governors. and recover as a nation over the weeks and months ahead. The unknown can be scary, leading to stress Above all, we need to be in contact with one another, and anxiety, which in many cases is heightened as now more than ever. We must be smart, but we will we have children to care for with us at home. As we get through this. Just as contagions of times past, address this challenge together, Brennan will be a this will also pass—just as other generations have resource that recognizes the physical, mental, and risen to the challenge, we will do the same. It is our financial toll we all face. The COVID-19 crisis will turn to shoulder this time of burden, so that we may hit each of us differently; if you are in need of help, provide a thriving country to our next generation. please let us know. “We are our brother’s keeper.” Stay safe, stay healthy, and keep focused on the light and good things ahead of us. Our present circumstances will likely continue for many weeks or into the summer months. As a Matt Binsfeld President and CEO Up-to-date Brennan News Regarding COVID-19 https://www.jfbrennan.com/en/news-covid19

SAFETY Brennan Incident (608) 881-8911 If an incident occurs: 1. If it is an emergency call 911 first 2. If it is not an emergency, call the Brennan Incident Hotline. The Safety Department will help coordinate the next steps. 3. The Safety Department will assist you in contacting WorkPartners to speak directly with a healthcare provider. What: The Brennan Safety & IT departments have developed an Incident Hotline to assist field personnel when an incident occurs on a jobsite. Why: An ongoing issue that has been identified by field personnel is the inability to reach someone in the Safety Department at the time of an incident. We recognize how frustrating this can be during this already stressful time. This hotline will streamline the reporting and response process, by allowing field personnel to call ONE number and alert SIX phone numbers in sequence. Who: When an incident occurs on a job site, timely reporting and response is extremely important. When calling the Brennan Incident Hotline one phone number alerts six different phone numbers in an established order. The alert order is as follows: Tim Butz, Vic Buhr IV, Steve Skau, Dan Palen, Dianah Colburn, and finally BMI Dispatch. The hotline will automatically dial the above personnel’s phones in sequence. Meaning, if Tim is unavailable Vic’s phone will ring automatically and the system will continue to autodial each phone until someone answers. When: The hotline does not take the place of 911. If a true emergency incident occurs 911 should always be your first call. The hotline is to be used as your first call during non-emergency incidents, and as your second call during an emergency incident. When a non-emergency incident occurs on a jobsite and you call the hotline, your safety team will assist you in deciding what needs to happen next. Where: Please create a new contact in your phone titled “Incident Hotline” and add the phone number (608) 881-8911. The hotline phone number is also available to you in the global address book. We hope this will be a valuable tool and resource to field personnel during the unlikely event of an incident. If you have any questions, comments, or suggestions please reach out to the safety department. After reporting your incident. A Brennan Safety Department representative will tell you whether WorkPartners sounds like a good fit for your situation. Once working with WorkPartners, please keep your Brennan Safety Department contact informed throughout the process.

WorkPartners Information: To give employees more support when a minor injury occurs, we have retained WorkPartners integrated health solutions to assist with our response. This service will allow all employees to access immediate medical attention for minor injuries as well as give better direction to those who are assisting. This service is available 24/7 at no cost to our employees. Please familiarize yourself with posted information located on all job sites and in the shop. We all must know how to respond when an incident occurs. If you have any questions regarding the WorkPartners service, please contact Steve Skau or Dan Palen

BUSINESS DEVELOPMENT Introducing the Brennan Br and Book & Style Guide Ever wonder where you can get support in ordering logo wear for your crews, or what paint colors we use on all of our equipment? Or how about who you can contact for business cards? Get your copy! 1. Hard copies are available in the Brennan lobby or contact Angela Callaway ([email protected]). 2. Electronic copies are available on the intranet and the Marketing Department’s public drive. M:\\Public\\001a BRAND BOOK Well, look no further! THE 2020 BRENNAN BRAND BOOK AND STYLE GUIDE HAS BEEN RELEASED! The Brennan Brand Book is a resource to everyone at J.F. Brennan Company and Brennan Marine, regardless of position. It covers a wide range of topics from the correct use of our name to how we manage job site and harbor tours. After all, the way each and everyone one of us represents Brennan is incredibly important. So you may ask… What is a brand!? Our brand is the image and personality we project to clients, employees, industry partners, suppliers, and the general public. It can be tangible, something we can touch and see, or intangible. Tangible Intangible » Safety » Our promise » Quality of our work » Reputation » Clean job sites » Cultural values » Positive attitudes » Customer experience » Professionalism » The way we communicate

THE BRENNAN BRAND The Brennan Brand is our identity in the marketplace that creates familiarity and awareness of our reputation. It attracts audiences who recognize the value we deliver and helps convey our message and culture. Our brand represents a firm based on trust, expertise, and quality. OUR PERSONA At Brennan, we aim to be a premium service provider on whom our clients can depend for solutions to complex maritime, environmental, and infrastructure challenges. Our clients prefer value, trust, and support over low-cost alternatives. We are a group of marine professionals who focus on the inland waterways of the United States and we serve those who operate on them. We are not a general contractor with a broad range of services. We go the extra mile to support our clients because when they succeed, we succeed. SOME OF THE ITEMS YOU’LL FIND INSIDE: 1. The proper use of our company names 2. How did we get the name J.F. Brennan Company? 3. How, where, and when we use our logos 4. Official corporate colors 5. Details on ordering logo wear 6. Paint colors and logos for equipment 7. Communication best practices 8. Publication and interview policies 9. Photography and drone policies 10. Jobsite cleanliness standards 11. Professional attire basics 12. Jobsite tour support 13. Sales and marketing resources 14. Business card resources 15. Brennan office locations and contact info IN ADDITION TO THE BRENNAN BRAND BOOK, WE INCLUDED THE FIRST-EVER STYLE GUIDE. Let’s face it… These days we all have to write. Whether it is a proposal, work plan, email, or even a text message, writing is a big part of our lives. (I know what your thinkining. We build things, run dredges, move barges, and fix equipment, so why do we have to be good writers? To be honest, most of us haven’t taken a writing course since 7th grade English class.) Regardless of your position, you should care how you write because not only does it represent Brennan, but more importantly is represents you. Yes, you! You have your own personal brand, and when you send that un-reviewed email, it will most likely give the person you sent it to the wrong impression. You know you are good at what you do, we know you are good at what you do, make sure those you communicate with also gain confidence in your expertise. You can do this by continuously improving the way you write. So to help you, we asked our resident writing guru and published author Gayle Edlin to help us put some writing tips together to include in our brand book. You now have a resource that helps you understand the difference between passive and active voice, how to use abbreviations, how to represent dates and numbers when writing, and much more. And, what would a style guide be without addressing the most controversial punctuation mark on the planet… the comma?!

CIVIL Driving Pile and Improvements at Rock Island River Terminal By Matt Hogan The Civil group was contracted by Alter Logistics This will be supplemented by new mooring structures, Company (Alter) as their prime contractor to perform fendering, a concrete cap apron, and new concrete pile driving and major site improvements to their pavement along the wall’s footprint. Rock Island River Terminal (RIRT) in Rock Island, IL. Brennan was selected as the low bidder for the Our crew, led by Superintendent Brad Dvorachek, project; however, our team and Alter are not strangers. mobilized back in December and we will complete the The Civil group recently performed site work under project this April. Brennan subcontracted excavation, subcontract at Alter’s St. Paul Terminal in St. Paul. The site drainage, and pavement activities to McCarthy Estimating & Project Controls group worked in tandem Improvement Company of Davenport, IA. This has with the Civil group to provide competitive pricing and been a great partnership for both companies. performance scheduling for base bid items as well as alternates for a larger linear footage of new sheeting The old seawall at RIRT surpassed its serviceable wall. After some negotiation and clarification, Alter lifespan and was showing signs of significant elected to award the alternates. deterioration after years of use. However, we were able to use it as an anchor wall for the new seawall by When complete, the client will have the benefit of cutting the old sheeting to an elevation 2FT above the approximately 515 LF of new seawall to use for \"normal pool\" elevation and reinforcing it with a waler transloading commodities on the Mississippi River. system. Welding cap plates for the downstream Levi Dondlinger signaling to move materials Crew utilizing the driving template and mooring pile structures vibratory hammer to drive sheetpiling

Levi Dondlinger and Quentin Thorson Driving piling Cohl Kueter & Jeremy Kroll welding place welding mooring pile cap plates plates for permanent waler installation As a team, we were bound by strict US Army Corps of seawall sheeting preserved valuable workdays in the Engineers (USACE) permitting requirements that only winter construction schedule. These saved days, along allowed excavation and completion of the seawall in with increased manpower and a second crane, enabled segments. This wall and facility provide flood protection construction to continue while river levels cooperated to the city of Rock Island. Therefore, a tight schedule with waler installation. Our crew expedited and installed mandated efficient utilization of all construction days to an extra 1,800 LF of piling within the project window— turn the site back over to the owner for the beginning of all things being equal, including weather, river days, etc. the 2020 Mississippi River shipping season. Our crews got off to an impressive start and have set fantastic Brennan is currently moving to complete our onsite production numbers. concrete work so that McCarthy can finish the concrete pavement at the seawall’s edge. It has been a pleasure A noticeable project delay occurred when our crew working with such a great project team and client—a noted irreparable deterioration of the existing wall. wonderful way to bookend our record 2019 construction Brennan’s onsite leadership and management team season while kicking off busy 2020 season. This was a worked with Alter and their design engineer to offer great winter project, and through hard work and great repair concepts and paths forward to complete the communication our crew was able to discover several project on time. In fact, the crew’s innovation in efficiencies that will increase our competitiveness on implementing a simple sheeting template for driving the future projects.

Getting Started: Working from Home By Gayle C. Edlin Working from home sounds easy to some and impossible to others; truthfully, it usually includes both positive and negative aspects. Family members, including pets, can pose complications to a structured workday, as can the absence of interactions. Delays in communications between coworkers, who may experience differences in connection strength or data transfer speed, can be frustrating. A wide variety of factors influence comfort and productivity when you work remotely—some may surprise you. Working from home shares similar physical challenges to working on a jobsite from a trailer. But your “new coworkers” may have even less respect for your personal workspace, and perhaps more determination to distract you than assist you … they may even meow or bark at inconvenient times. There’s a possibility that you’ll have to adjust your preferred work times or methods, and most people struggle with focus, especially when starting to work from home. Just as we innovate in the field, we also need to evaluate our unique home situations to improve our remote-work environments. TAKE CARE IN SETTING UP YOUR WORKSPACE. It’s not necessary to spend a lot of money on your office away-from-the-office. One quick fix involves raising Office settings consider ergonomic factors to promote your laptop to the level of a “real” monitor by setting it short- and long-term physical health, but many home on a sturdy cardboard box on top of your desk. Add a workspaces fall short in this regard. This is especially standard keyboard and mouse to the USB ports, and you true when employees are new to working from home, or have a significantly improved ergonomic setup. If you are doing so due to unexpected circumstances. While have a spare monitor, you can plug that directly into your desk work contains fewer significant immediate risks laptop—presto, dual screens. to physical health than many other occupations, it’s far from problem-free. Inherent risks of desk work include Other factors to consider: cumulative trauma disorder and repetitive strain injury » If your chair doesn’t have fully adjustable armrests (RSI). These conditions, which can become chronic, can be prevented by proper ergonomic workspace setup. (height, width, pivot, and forward/backward glide), use a chair without armrests. Proper armrest fit For more information, visit a reputable resource in office is critical to preventing future problems and fixed ergonomics. Start with the National Institutes of Health’s armrests rarely provide individually appropriate sizing. Division of Occupational Health1 and Safety or the This can cause recurring pain in your wrists, elbows, University of Virginia’s Office of Environmental Health and shoulders. and Safety.2 As tempting as it may be to spend your » If you notice yourself stretching your neck forward working day on your couch or among a pile of pillows, or to one side, pay attention: this can lead to neck or this strategy will almost certainly fail. Wrist, neck, and back strain, as well as tension headaches. Reposition back pain frequently result from improper positioning, your monitor(s) and check your posture throughout particularly if you work this way for long periods of time. the day. You may also need to adjust the brightness Not-so-fun fact: Carpal tunnel syndrome, the result of repetitive wrist motions, is a fairly well-known injury in office work. Cubital tunnel syndrome is a similar chronic condition caused by poor ergonomics such as resting your elbows on improperly positioned armrests, causing numbness and tingling in the fourth and fifth fingers of the affected arm. It can also result in receiving a shock of pain—as if you hit your so-called “funny bone”—even when you do something as innocuous as press your elbow into a cushioned surface.

of your screen to prevent eyestrain, as your home STAY (VIRTUALLY) CONNECTED. likely has different interior lighting than the office. » Whether you have a professional or do-it-yourself Many employees find it challenging to stay connected home office setup, take frequent breaks. Walk around with the rest of their team when working remotely. and stretch for 5 minutes every hour to help reduce Use phone calls and virtual meetings for strategizing your risk of cumulative disorders and repetitive strain and longer conferences. You may even choose to get injuries. If you have children at home, these breaks up and move around while on a call—just be mindful are a great time to engage in a quick dance-off or that you could wander into areas where your phone other fun activity with your kids. has poor reception. Email in cases where you foresee greater chances of raising additional discussion points BE PROACTIVE IN MANAGING STRESS. or concerns. Instant messaging systems such as Cisco Jabber offer both one-on-one and group communication New working environments, like new jobs, inevitably options, and lend themselves well to “chat” types of cause stress. Even good stress—as when you find conversations. yourself excited by the prospect of working from home— can lead to feeling overwhelmed or exhausted. Some Microsoft® Teams is a robust tool that you may want to people find that they miss the “transition” of the drive utilize as well. Teams encompasses all of the services to work as a time to prepare for the day ahead while mentioned above within a single program. Check with others long for the ability to stop by a coworker’s desk to your group to see who has experience using Teams so chat. You may find it hard to concentrate on work in your you can use as many relevant features as possible. personal space, a place where you might otherwise not think about work at all. Practically speaking, staying connected and online when you live in a smaller community, or in a rural setting, can These are just a few concerns employees experience pose additional challenges. when transitioning to working from home, even under the best of situations. Experiment and share your ideas with » Check for updates to your router’s software. If others to mitigate problems as you encounter them. possible, you might also want to upgrade your wi fi. » If you find it difficult to get into the workplace » Password-protect your home system and minimize the headspace at home, try taking a walk before work. number of devices accessing it during working hours. Substitute activity in place of your commute may help you refocus your mental energy, and physical » If you connect to the Internet via your phone’s mobile exercise also benefits the mind. Lunchtime or right hotspot, plug in your phone during use and close any after work can be another good time to take a literal non-essential applications for best results. You may hike and regroup. also need to close more programs on your computer » Some people find that simply dressing in work than you would if you were working in the office. attire—rather than, say, pajama pants (no judgment)—helps them prepare for an “at-home” » In cases with persistent connection problems or workday. If that’s not you, no problem; just make sure extremely large files, you may find it more efficient your webcam is properly adjusted before use. to copy files to your hard drive when working on » Schedule a brief call or online chat with a coworker them. Consider adopting a specific routine to make you would normally see in the office to help retain a sure you’re copying the updated files to and from sense of normalcy and social connection. Working the correct locations (for example, copy files from relationships can be just as valuable as personal a window positioned in the upper portion of your relationships, and many people count at least some screen, and paste to a different window positioned in coworkers as friends. the lower portion of your screen). » As much as is practicable, dedicate a specific space in your home to serve as your office. Try to find a low- » Disconnect from the network at the end of each traffic area where you will encounter fewer distractions. working day and shut down your computer (or Let your family know that when you’re in this space, reboot). If you’re using a hotspot, remember to turn you’re working, and try to keep regular hours. that off as well. Adaptations such as using noise-canceling headphones or running a white noise machine may also help. You » Contact Brennan Information Technology (IT) with can also find apps to provide background noise, some questions or concerns. of which allow you to mix a variety of sounds.3 Every working situation poses challenges and requires adaptation, and working from home is no exception. A little creativity and experimentation go a long way to making your home office comfortable and productive. As a bonus, you can make your coffee exactly the way you like it! You might not even have to share. 1https://www.ors.od.nih.gov/sr/dohs/HealthAndWellness/Ergonomics/Pages/prevention.aspx#Computers 2https://ehs.virginia.edu/Ergonomics-VDT.html | 3https://www.relaxmelodies.com/

RAIL Pig’s Eye R ailroad Project By Dennis Jonjak Brennan was recently awarded 2 contracts with Union Pacific Railroad (UP) to replace damaged timber shear fencing at 2 swing bridges in St. Paul, MN. Advocates for the marine industry have been pushing for reconstruction of the shear fences in order to prevent damage to both the bridge and vessels. Brennan has been heavily involved in repairing UP’s Twin Cities infrastructure, largely due to the proximity of Brennan’s St. Paul yard to the project locations. To complete the repairs, we are utilizing the 9299 American crawler crane, spud and material barges, and M/V Barbara B. The first bridge Brennan repaired was the Hoffman 349.5 Bridge. Due to past flooding and vessel collisions, the west bank of the bridge was missing its entire upstream shear fencing. The new shear fencing design is broken into three sections with a total length of 368 FT. The first two sections equal 105 FT and are oriented at a radius of approximately 917 FT starting from the bridge’s west abutment. The third/upstream section measures 158 FT and is oriented at a 20-degree angle back toward the west riverbank. The timber shear fence foundation piling consists of 75 pairs of 1 plumb and 1 battered 12-IN-diameter southern yellow pine timber. Each pile pair is spaced at 5 FT center and each piling is 50 FT in overall length. Crews utilized a DELMAG® D19 pile hammer to drive the piles into the river bottom.

After driving the piles, crews braced the rows of plumb and batter piles together using a combination of 12 IN x 12 IN and 3 IN x 10 IN timber members. Running along the entire length of the piling, 9 rows of 8 IN x 12 IN face timbers provide the protective guide surface for vessels to contact. Crews then installed pile clusters to strengthen the end of each shear fence section. Each cluster consisted of 7 piles driven into the river bottom and secured together with steel cables. We have encountered several challenges since the project began, such as removing the existing timber pile remnants and debris along the path of the new shear fence drive line. Any items not removed would pose a risk that could obstruct the installation of the new piles. To resolve this problem, crews utilized Brennan’s John Deere® 470 long-reach excavator to reach and remove debris from the driveline. Protecting an existing Sprint® fiberoptic cable running below the shear fence orientation presented another challenge. Crews met with Sprint technicians before the start of the project to review the depth of the cable and establish a plan to protect it. Brennan and Sprint identified the location of the cable using ground-penetrating radar and placed the foundation piles on either side of the cable. Crews also battled weather and ice conditions. Several times, large masses of ice posed the risk of pushing Brennan’s marine equipment into the bridge. In addition to those challenges, our crew did a great job working with the UP to coordinate bridge openings. As of March, our crew completed all foundation pile installation on the Hoffman 349.5 Bridge and have installed half its bracing and face timber members. Upon completion, crews will mobilize upstream to the second and final bridge of the project, known as the Mankato 2.29 Bridge. Crews installing face timbers Crews finishing pile installation

BRENNAN MARINE BMI Oper ations Start at Brickeys Quarry By: Karl Berthelot On February 1, 2020 we started a new operation at APAC Max Hernandez, Jeremy Akins & Wyatt Wheeler Tennessee Brickeys Division (Brickeys) in Bloomsdale, A view from the conveyor dock looking down river Missouri. Brickeys is a rock quarry that has been in business for many years and is part of a much larger company that handles many types of stone and sand. During our negotiations, Brickeys discussed a 4-million- ton expectation for 2020 with much of the stone heading to the gulf coast area. During our first month of operation the Brickeys docks worked a 6 day a week schedule at 12 hours per day averaging nearly 10 barges per day. We have a 10-man crew on a schedule to cover 24/7/365. The crew experience ranges from new crewmen to nearly 20 years on the river. Max Hernandez catching the rope Jeremy Akins & Wyatt Wheeler

Introducing: The M/V Elizabeth Marie In December, we purchased the M/V Miss Mary Jean from D&S Towing out of Houma, Louisiana. The vessel is 2,000 horsepower and fully equipped for the task at hand. The vessel is 71 FT long and 27FT wide built in 1975 and then rebuilt in 2014. After Brennan Marine purchased the vessel, it was renamed the M/V Elizabeth Marie after Adam Binsfeld's wife Beth Binsfeld. This vessel will begin it's new life with Brennan at the Brickeys Quarry harbor. Future Growth Expected in Ste Genevieve Area We are excited to have a new operation to add to Brennan Marine's portfolio and are very excited about the future growth that we expect in the Ste Genevieve area in coming years. As a team, we are committed to becomming a valued asset to our line haul customers and harbor clients in the area. We will continue to pursue new opportunities and where possible make our own opportunities so that everyone will have a chance to learn and grow with Brennan.

innovations Brennan’s IT Department Creates New Wireless Infrastructure for Latest BMI Contract By Brian Jerzak Once the Brickey’s contract was finalized, Brennan’s Information Technology Department (IT) went to work figuring out what type of internet connections were available for the office and vessel operations. Not only did we need to acquire a high-speed internet connection for the site, but also, we needed to be able to provide a wireless connection for Brennan Marine’s new vessel, the Elizabeth Marie. The coverage area on the river for the Elizabeth Marie needed to extend to the upper and lower fleets and all points in between covering over 9,000ft or 1.72 miles. It was agreed that the design of this network needed to be very similar to what was put in place at the LafargeHolcim harbor in Ste. Genevieve, MO. So, we contacted Lightwave Communications (Lightwave) and began discussions on some possible options. Lightwave is a fixed wireless internet service provider located in Festus, Missouri, not far from our Brennan Marine sites. Founded in 2011 by brothers – not unlike Brennan – Lightwave provides custom solutions and access to internet services in the St. Louis area. Quarry wireless coverage Wireless links from Bloomsdale

PART 1: INTERNET SOLUTION Grain tower in Prarie Du Rocher, IL Working together with Lightwave, we faced a fair number of Solar sight challenges while trying to get an internet connection to the Brickey’s Solar sight site. It was impossible to get line of sight from Lightwave’s own internet towers to the quarry based on heightened elevation, but there Grain silo lightwave antennas on left was line of sight to Illinois. We searched for an internet service provider in Illinois that might have been able to assist us, but due to regulations between Missouri and Illinois the internet service provider was not able to help us out. We then took it upon ourselves to design and create a wireless network of our own. Fortunately, Lightwave has a tower located inside Bloomsdale’s city limits that was approximately 5 miles south of the quarry. This tower was able to get line of sight to a 140 FT tall grain tower approximately 8 MI away across the river in the small town of Prairie Du Rocher, Illinois. An agreement was made to use space on the grain elevator and to install multiple antennas to receive a signal from the Lightwave tower. From there, we were able to work with Brickey’s quarry to utilize a nearby hill with an existing solar site so that we could add our own solar equipment and antennas (see photos on the right). With all the pieces in place we were able to backhaul the signal from the grain elevator in Illinois to the solar site on Brickey’s hill. The solar site on Brickey’s hill is now Lightwave’s demarcation point where they hand off high speed internet to Brennan’s network equipment. The next step was to now send the internet signal down to the office and to a spot near the shore for the river coverage. PART 2: WI-FI SOLUTION Our wireless internet access solution (WI-FI) needed to accomplish two things. First, we needed to get a signal down to the Brickey’s office to be able to provide internet for onsite Brennan staff. This connection would also be connected back to our La Crosse office for access to our network resources. Second, we needed to get a wireless connection down to the shoreline area to be able to create the wireless connection point for the Elizabeth Marie. A directional antenna was installed on the office and it connected back to the solar site with ease. The challenge for us was delivering the wireless connection to the river for the Elizabeth Marie. We needed to find a location with a high enough elevation that would allow for clear line of sight upstream and downstream along the river. After exploring all our options, Brickey’s allowed us to utilize a 60 FT tall river structure on the property for the installation of electricity, an omnidirectional antenna and all the necessary radio equipment. The Elizabeth Marie is now able to have high-speed WI-FI throughout the entire harbor and fleeting area while out on the river working.

ENVIRONMENTAL Brennan recently attended the 9th annual Delaware Wetlands Conference focused on conserving wetlands in the Mid-Atlantic Region. The conference attracts more than 320 wetland for our recent work in Rhode Island. As part of the experts and enthusiasts from Maryland, Delaware, conference, Brennan exhibited: allowing us to show Washington D.C., Pennsylvania, New Jersey, New several engineers and consultants the type of work York and North Carolina. Together we share the latest we perform our experience and the “cool equipment” in wetland research, innovations, outreach, education, we bring to the table. and the progress of conservation programs. The Mid- Atlantic Region is a new market for Brennan, but due The conference offered several different sessions to our successful work at Massey’s Ditch for the State covering everything from wetland biology, funding of Delaware, we have been able to plant a flag. It was strategy, coastal resiliency, and restoration. amazing how many people at the conference knew about the Massey project and how well it was going. Director of Business Development Andrew Timmis presented “Beneficial Use of Dredge Materials for Brennan has been at the forefront of wetland Salt Marsh Restoration in Rhode Island” which remediation and restoration for more than 20 years summarized the construction and lessons learned of and was most recently highlighted and honored the Ninigret Pond and Quonochontaug Pond projects. Representing Brennan, pictured below: Project Manager for Massey’s Ditch David Horne, Hydrographer Mallory McCormack, and Andrew Timmis

SAawfeatryd Final list of 2019 Safety Each month, the Brennan Safety Committee will Award Winners: select a winner from the previous months nominees to receive the safety award. Any Brennan employee » January – Mike Converso can nominate another employee for the award through » February – Tim Eaker a written submission. Safety committee members will » March – Travis Schulte select a winner based on who they believe exemplifies » April – Justin Brewster the best safety traits and behaviors. The nominee » May – Kelvin Dondlinger should be someone who goes above beyond normal » June – Alex Cook safety tasks required of every Brennan Employee. » July – Jerimiah Fritsch » August – Scott Brueggen WHAT IS THE » September – Ryan Marciniak BRENNAN SAFETY COMMITTEE? » October – Lake Carnegie The Brennan Safety Committee was formed to help Capsize Canoe rescue group- reduce the risk of workplace injury and illnesses, Taylor Looker, Daniel Ferrira, promote employee safety and provide the opportunity Chad Defoe, Cletus Bowe. to discuss safety concerns among employees from » November – Craig Arneson all levels of the company. The committee provides » December – No Nominations an opportunity for employees to work together to discuss previous incidents, current safety concerns Congratulations and thank and develop plans to prevent potential hazards. The you for your diligent work! committee provides the opportunity for different members of the company to take a leadership role on safety initiatives. The Committee is made up of 16 active members, which will rotate on a yearly basis. If you would like to submit a nomination for the safety award, please submit your written nomination too Steve Skau, Megan Pronschinske or Tim Butz.

UNDERWATER SERVICES As most of you already know, Industrial the former Industrial group and Dive group + Dive have joined into one business unit called Underwater Underwater Services. Services Group By Dan Wibralski However, many of you may still be curious what drove this decision. Let's dive into that question (pun intended). There are many beneficial reasons for a merger of the two groups. The following reasons are perhaps the most impactful. There was a major overlap in the scope of work performed between the Industrial group and the Dive group. Consequently, there was a major overlap in the people working between the two groups. The two groups constantly worked together in nearly all aspects of business. Essentially, the two groups were already performing as one group in many ways. Officially joining the groups enables a more efficient and streamlined operation. In addition to making operation more streamlined, the joining of the groups better situates resources to respond to an enormous potential. The interest from new clients in our specialized capabilities, especially our underwater construction capabilities, has been growing exponentially. We anticipate this interest will continue to transform into opportunity. Our goal is to take advantage of the growing opportunity in an intelligent and meaningful way. By combining the resources in the two previous groups, we've become one strong group with a diversity of roles and capabilities. We now have an extraordinary combination of eager and energetic project management and project coordination capabilities, extremely talented construction superintendents and other top side leadership as well as arguably one of the strongest groups of divers in the country. This puts us in the best possible position to take advantage of the growing opportunity. There are many advantages in growing a business when the right opportunity exists. Perhaps the most important concept is successfully taking advantage of opportunities to grow a healthy business, which almost always provides opportunities for people to grow their careers. We've already been fortunate enough to experience this.

Dan Wibralski VP of Underwater Services Diver Erik Henry at Snake River There are many talented Brennan people that were once hard- direct: 608.519.5319 working field personnel (divers, carpenters, laborers, operators, cell: 608.317.0681 etc.) who have moved on to become superintendents, general [email protected] superintendents, project managers, safety managers, estimators, J.F. Brennan Company, Inc. directors and VPs. That is already especially true in the area of 818 Bainbridge Street Underwater Services. These career growth opportunities will continue La Crosse, WI 54603 to develop if we continue to grow in a meaningful way. Combining the two groups into Underwater Services not only leverages the ability to Justin Scherf grow, which provides new career advancement opportunities, but it also allows us to provide diversity to all our current positions and roles. Director of Underwater Services These reasons are but a few of the benefits of the combined group, but as mentioned, they are some of the most important ones. The successful joining of companies like Pro Dive and Viking Marine Services with Brennan has often been described by saying 1+1=3. In other words, joining the right combination of people and resources can cause growth that exceeds what simple math can't explain. I truly believe the combination of resources that now exists in the Underwater Services group will prove to be another example of that. Jacob Shultz with diver Aaron Rowling direct: 608.519.5344 cell: 815.979.8973 [email protected] J.F. Brennan Company, Inc. 501 Illinois Ave Ottawa, IL 61350

The Exceptional Apostrophe By Gayle C. Edlin As with spacing between sentences and various other facets of the English language, the use of apostrophes developed over time. It’s surprisingly difficult to keep up with this small punctuation mark and the rules governing its use. Not to mention the apparent exceptions: it’s (a contraction) and its (the possessive form). But we’ll come back to that later. Question: “In the beginning, it was clear how to use the apostrophe?” Answer: “Well, not quite. It’s never actually been clear.” Mignon Fogarty interviewing Ammon Shea, author of Bad English. Right or wrong, change happens everywhere from traffic communication structures. In general, avoid using laws to language. Even apostrophes experience the contractions when representing your employer in writing. An imposition of seemingly arbitrary prescriptions for proper exception might occur when you write a contact with whom use. While we codify rules now differently than earlier you have a strong, established working relationship. You writers, most modern apostrophes show up for the same can use contractions when you want to seem more friendly basic reasons as they did historically: to indicate omitted and natural; completely avoiding contractions in writing is letters in a word or group of words (contraction) and to sometimes interpreted as rigid or indifferent. express possessive or other close relationships between things (genitive case). Bottom line: Use contractions sparingly in business writing. Let’s Talk About Contractions Merriam-Webster states that apostrophe use began in the Apostrophes’ Possessive Expressions early 1500s; other sources blame folks in the late 1400s for About a century after the introduction of the apostrophe, it this “innovation.” At that time, few people could read and gained traction in a new area: the genitive case. This use write, which may account for some of the divergent practices of the apostrophe can indicate possession (e.g., Brennan’s that occurred. By comparison, 86% percent of today’s dredge) as well as other close associations like duration worldwide population aged 15 years or older are literate … (e.g., a week’s vacation). Around the time of the apostrophe’s and have strong opinions on almost everything, including creation, writers denoted possessive and similar conventions related to punctuation. relationships by adding es or ys. Eventually, they stopped bothering with the e or y, leaving a simple s (e.g., managers At first, deploying the apostrophe demonstrated removal of review, which we would now write as manager’s review). It a letter or letters at the point where the extraction occurred. seems as if the possessive apostrophe may have originated Certain irregular uses, including replacing unpronounced from a contraction, replacing an absent e or y. letters (walk’d for walked) and random/poetic insertions (ha’s for has) notwithstanding, the original practice of indicating But a group of historians believe that adding an apostrophe contractions with apostrophes persists today. to show possession arose out of confusion regarding a different contraction. Established convention of the time Words like I’m, we’ll, they’re, who’s, doesn’t, etc. appear included the word his to show the relationship between the frequently in modern writing. We use the apostrophe person and the thing he possessed. This means that people to replace the letters we leave out, and most people in the late Middle Ages would have phrased our previous fluent in English understand common contractions. example this way: manager his review. As the apostrophe However, business practices tend to require more formal

gained popularity, writers of the time could have looked at this Sources: structure and assumed that some poor soul forgot to add an • https://www.quickanddirtytips.com/education/grammar/ apostrophe to replace the first part of “his.” And we’re back to manager’s review. the-history-of-the-apostrophe • https://en.wikipedia.org/wiki/Apostrophe Yeah, that’s weird, right? Perhaps it made sense at the time. • https://www.merriam-webster.com/words-at-play/ In addition to showing up in contractions, today’s apostrophes history-and-use-of-the-apostrophe also continue to reflect relationships between words that indicate • https://www.technologyreview.com/s/417380/the- possession or other close association (e.g., crew’s work). The possessive form typically involves adding ’s to the word that “owns” curious-case-of-the-evolving-apostrophe/ the other word. As the example illustrates, this system works well • http://wmjasco.blogspot.com/2011/08/possessive- for singular possessives. For plural possessives ending in an s, a second s after the apostrophe is not required. Add only the apostrophe-his-origin.html apostrophe to show possession by a plural noun that ends in s • https://ourworldindata.org/literacy (e.g., crews’ work means the work of two or more crews); do the • https://theoatmeal.com/comics/apostrophe same for other words that end in s as well (e.g., Louis’ application). Bottom line: » For singular words that don’t end in s, add ’s to show possession of the following word; for plural words or words that already end in s, add ’ (no extra s). » When confronted by an s that you’re not sure needs an apostrophe, take the irreverent-but-wise advice of the fine folks at The Oatmeal: “When in doubt, DON’T use an apostrophe.” It’s Only as Weird as Its Contraction Arguably the trickiest apostrophe situation of all, it’s and its seem like exceptions to apostrophe rules. You can think of it’s and its as abnormal if it helps you remember that they're different. It may also help to know that it’s is a contraction rather than a possessive, meaning it is or it has. The reason the possessive form, its, does not use an apostrophe is because it is a pronoun (a substitute for a noun) rather than a noun (person, place, or thing). You might say that it’s really its own rule. Well, I might say that. #SorryNotSorry Bottom line: If substituting it is or it has makes sense in the sentence, use an apostrophe (it’s); if not, don’t (its). The preceding test also helps clarify the difference between “it’s easy” and “the article finally reached its conclusion.”

By Paul Olander RivWeratReersptloarcaetPiaornk: Small Dredges Prove Useful in Downtown Waterways As the sun on the dredging season in SMALL DREDGE REQUIRED FOR CITY DREDGING the Midwest inland areas began to set, operations were starting to heat up This season, good fortune shone on the Environmental group as on the east coast. For a third straight we procured another winter restoration project in Rhode Island. The year, Brennan has had the opportunity general scope for this project remained along the lines of past work, to procure work in the milder maritime where we restore river depths to facilitate and improve water quality climate throughout New England during and fish migration, but this one came with a twist; its footprint was the winter months. These months are key tightly nestled within the low bridges and bustling infrastructure of for in-water work on the east coast as Waterplace Park in downtown Providence. they provide opportunities to revitalize salt marshes, re-nourish beaches and restore Providence is well known on the eastern seaboard for hosting its navigation outside of the fish migration sensational nighttime WaterFire events, which attract 1 million visitors and spawning windows. Generally, this annually to the downtown district. This portion of the Providence and work has been undertaken in and near Woonasquatucket Rivers is also crucial to the seasonal migration of the coastal salt marshes adjacent to the anadromous fish species. smaller resort communities. Over approximately 4 decades of urban influence which includes Superintendents: Chad Defoe and Zack Meyers Nate Volz with the Grand Cal Downtown with Capital in background

Brendan surveying a stockpile Aerial view of high-speed dewatering area Zack and Chad skimming floating debris run-off of road sand during winter weather, the river had the day lost due to pump and cutterhead cleanings. sedimented to the point where the aesthetics at low tide were beginning to lack, and the fish migration route at Beyond plastic, our team encounter and removed 16 certain low tides became nearly impossible. electric scooters and 17 bikes from the Providence and Woonasquatucket Rivers. The patience and PROVIDENCE AND WOONASQUATUCKET RIVER professionalism of the team ultimately persevered in DREDGING BEGINS the end, completing the goals of the project within the required time window and without any injuries. We began mobilizing personnel and equipment to the project site during early November. By Thanksgiving, the SMALL DREDGE MAKES IMPORTANT IMPACT crew had assembled our high-speed dewatering system IN DOWNTOWN WATERWAY some two miles away and moved the dredge Grand Calumet through and under a ridiculous amount of low- When it was all said and done, the dredge Grand Calumet clearance bridge spans to the head of the work area. A removed 12,395 cubic yards of sediment material, dedicated 12-member team worked diligently 24/7 from most of which was sand, and dewatered it for potential this point forward, focused on removing sedimented beneficial reuse in East Providence. This project was sand and debris from Waterplace Park beginning in the a shining example of the importance of teamwork and upstream extents progressing down. communication both internally and externally to Brennan. The onsite crew provided innovative and effective PLASTIC WASTE SLOWED RIVER RESTORATION solutions to the stakeholders for complex issues. In OPERATIONS return, the team had full support from our client; The Nature Conservancy, along with project partners; the Debris, mostly in the form of single-use plastic products, City of Providence, State of Rhode Island, Providence were comingled with the target material at staggering Foundation, Woonasquatucket River Watershed Council, proportions. This debris significantly hindered the and all the local residence of Providence, RI. effective operating time of the dredge and transport system and in many cases accounted for up to 40 % of

LOCK & DAM HeadsLtoocAkm&eDraenm By Wyatt Eaton

In October 2019, Brennan was awarded a contract with Ameren® Crew installing forebay wall struts Missouri at their hydroelectric power generating station on the View of the existing damaged forebay wall struts Mississippi River adjacent to Lock & Dam #19 in Keokuk, IA. Crew members erecting formwork for one of The work included modification of the existing water intake portion the corbel structures of the powerhouse to accommodate a new robotic debris handling machine. Ameren’s current method of handling debris is quite time Test fitting the strut prior to final grout placement behind consuming and involves removing each piece of debris from the chute the downstream strut mount bracket, and pier nose with an overhead crane and grapple bucket, as well as manually cutting up larger pieces of debris for easier handling. The new debris-handling machine will travel on a Brennan-installed rail system with a robotic crane arm and saw, making the process much faster and reducing manpower requirements. Brennan is installing 64 new steel struts that protect the forebay wall from any kind of impact by a vessel. The struts are spaced 12 FT apart and span 13.75 FT from the upstream forebay wall back to each pier. Our other major scope of work includes constructing concrete corbels around each forebay wall column to support the upstream crane rail on which the new debris handling machine will travel. We are also constructing a topping slab on the plant floor that will support the second stretch of crane rail. Ensuring consistency of alignments and elevations along the 785 FT stretch of the powerhouse necessitated many survey points. It is imperative to maintain the distance between the upstream and downstream rails within the acceptable alignment and elevation tolerances, or the new debris handling machine may not travel correctly. This project presents many challenges, including a strut-installation process that only allows Brennan to work on 8 struts at any given time. Furthermore, the downstream removal limits for the strut mounts are about 1 FT below water line, so the crew had to custom-fabricate dewatering boxes that would fit around the piers. Despite irregular pier geometry, the crew has devised some creative ways to seal around them in order to complete the work. For safety reasons, we perform our strut work from pipe floats that have been widened to fit between the forebay wall and intake trash racks. With this method, Ameren can run all turbine units while we safely work from pipe floats in front of the turbines—an extremely uncommon situation given the amount of turbulence. The reason we can work this way is due to our improved safety features to the pipe-float working platform and innovative methods the crew developed to reduce motion on the working platforms. The project site also poses difficulties with access because of its location in the middle of the Mississippi River. All deliveries to the powerhouse building must enter through the Illinois side and then be transported across the 4,315-FT-long dam via a one-way rail cart. The jobsite is stretched out over the length of the powerhouse and spans nearly 785 FT. To keep the process running efficiently, the crew must maintain an orderly work area so that CONEX boxes, toolboxes, and materials move quickly down the line as the strut and corbel work progresses to the north; we must also accommodate the topping slab work beginning from the south. With three separate scopes of work happening simultaneously, extensive scheduling and communication between Brennan and Ameren is necessary to prevent conflict between our work and their plant operations. There has been a learning process, but our team couldn’t have handled it better—thank you to all involved for your hard work and support!

2020 DSkaiy February 1, 2020

Brennan has partnered with a new Employee Assistance Progr am FEI Workforce Resilience has a 40-year history in enhancing workforce resiliency by offering a full spectrum of solutions, from EAP and organizational development to workplace violence prevention and crisis management. FEI offers a while variety of services to all our employees. » Stress related to work, family and personal life APEsrmsoipgstlraoanymcJeee.EFm. pBlroe » Balancing work and family » Coping with change and transition Work-Life » Grief and bereavement Services » Marital, family and parent-child issues » Emotional and mental health SYouupdeonr’th concerns FSienravFnicEceiIashl as a so » Problems with alcohol and drugs When you call for EAP services, please SYUouPdEoRn’Ht hUavMe tAo Nbe plan to spend up to 15 minutes with an EAP Counselor on the phone. This initial phone interview is the starting point for resolving your personal concerns. In order to do this effectively, time is needed to gain an understanding of your needs and link you to the best possible resources. CONFIDENTIALITY Confidentiality is strictly upheld in accordance with FEI principles and policies as well as federal regulations and state law. No J.F. Brennan Company, SeLrevigcaels information about use of EAP services will be disclosed Inc. to any party without written authorization from the individual CwGawelltwur.esfesoieuarcpe.csoomn,linuesername: brennanwww.fGeieeatpr.ecos served, or parent or guardian 1.800.638.3327 C when indicated. The only exception is when legal 1.800 mandate requires disclosure, such as when an individual poses a danger to themselves or others. Please do not hesitate to reach out to our Human Resources department with any questions.

ASSET MANAGEMENT Our First Amphibious Crane Manufacture Manitex Model 30102C Maximum Capacity 20,000 lb Maximum Reach 100 ft The latest addition to our amphibious fleet is expected to assist in Civil jobs, similar to the recent Xcel Energy© Transmission Foundation project in Nelson, WI; environmental work, any infrastructure replacement work in marshy conditions, and essentially any job that needed a “hook” to assist with other amphibious equipment. Thank you to all the fabricators and mechanics that had a hand in putting this piece together!

Asset Management Welcomes Travis Hamilton FLEET VEHICLE COORDINATOR Travis Hamilton joined the team in February as the Vehicle Fleet Coordinator. As our vehicle fleet has grown to approximately 180 vehicles plus over 100 trailers we recognized a need for a full-time person to manage all of this equipment. Travis came to us with multiple years of relevant experience managing fleet vehicles and is quickly getting up to speed with Brennan’s vehicle fleet. Paul will continue to set vehicle budgets, forecasting and purchasing of new vehicles. Travis will take over all of the day-to-day management of the fleet. This includes new vehicle setup, maintenance scheduling/tracking, distribution of pool/crew vehicles, purchasing of accessories and licensing/registration. Please begin using Travis as a resource for all of your vehicle needs. BACKGROUND INFORMATION: I was born and raised in La Crosse, WI. I have worked at Kwik Trip for eight years. My last four years at Kwik Trip I worked in the truck shop as a shop coordinator. WHY IS BRENNAN A GOOD FIT FOR YOU? I am excited to be here at Brennan. I have friends that work here at Brennan and say how great of a company it is which made it an easy decision for me to apply here. I am thankful for the opportunity to take on this new role and with my experience from Kwik Trip to help grow and make the automotive fleet more efficient. ANY FAVORITE SPORTS, SPORTS TEAMS, SHOWS, MOVIES, ETC.? My favorite sports are basketball and football, I’m a big Bucks and Packers fan. FUN FACT: I got married back in October.

MILESTONES & DATES TO REMEMBER Years of Service Anniversaries 5 Years 01/5/2015 20 Years 01/17/2000 Mike Rice 01/19/2015 Tim Tolvstad 02/28/2000 Matthew Vishino 04/1/2015 Andy VonArx 04/17/2000 James Dahl 04/1/2015 Timothy VonArx Nicholas Dvorachek 04/6/2015 02/25/1980 Elliot Kast 20 Years 03/1/2010 Dan (Ringo) Hartert 10 Years 03/1/2010 Daniel Huycke Adam Thorson Mark your Calendar! MAY 25, 2020 - MONDAY Office Closed for Memorial Day APRIL 3, 2020 - FRIDAY Town Hall Meeting MARCH 20, 2021 - SATURDAY Brennan Annual Celebration - La Crosse Center APRIL 10, 2020 - FRIDAY Office Closed for 1/2 day for Good Friday JAMES BRINK 12/17/2019 CARPENTER UTILITY New JEREMY AKINS 01/1/2020 DECKHAND Hires MATE KOLTEN BAUGHMAN 01/1/2020 PILOT SR BD MANAGER JUAN MENDOZA 01/1/2020 MATE DECKHAND WILLIAM OGDEN 01/1/2020 DECKHAND DECKHAND RORY ALSBERG 01/2/2020 CARPENTER AP SUPERVISOR STEVEN KELLEY 01/20/2020 LABORER DECKHAND LOGAN LUCAS 01/20/2020 AP SPECIALIST OFFICE COORDINATOR MICHAEL PRESLEY 01/20/2020 DIVE EQUIP MAINTENANCE PILOT WYATT WHEELER 01/20/2020 OPERATOR FLEET COORDINATOR BETHANY CASSIDY 01/27/2020 INTERN SITE SAFETY MANAGER STACY KEWITZ 01/27/2020 SYSTEMS ANALYST PROJECT MANAGER SCOTT PARKER 01/27/2020 COREY BOLGER 01/28/2020 LAURA SHAVER 02/1/2020 MARY DAVIS 02/10/2020 DAVID MATEIKA 02/10/2020 ANDREW TOPPER 02/11/2020 PATRICK DEPASS 02/13/2020 TRAVIS HAMILTON 02/17/2020 TYLER HENSON 02/24/2020 JEFF THOMPSON 02/24/2020 WILL TWEED 02/24/2020 FARHAN-KALEEM KHAN 02/28/2020

Dredge Days Was a Success The environmental group held Dredge Days in February. Over 55 project managers, surveyors, superintendents, and foremen were in attendance. The event took place over five days, with ten different classes that employees participated. Matt Binsfeld and Greg Smith started the event by thanking the team for their long hours and hard work and provided a company update and some statistics from the 2019 season. The training included a seminar on Emotional Intelligence, Dreducation presented by one of our key equipment suppliers DSC and hands-on training by Weir Pump. The group also had a fun night of ax throwing and an Escape Room. The exercise allowed us to celebrate our successes but also allowed an open forum to review our weaknesses in 2019 and how we will improve in 2020. Through this process, Brennan remains committed to providing the training we need to be the best in class in the environmental industry. A special thank you to all who attended and our presenters.

Ken Steiber { }“Little Guy” with a big personality Kenny started his career at Brennan in 1962, back when J.F. Brennan Company was relatively new, and the office was in Jim Brennan’s house. Ken was initially hired to help with the fabrication of sectional barges, where he was tasked with crawling inside to wire-brush and paint. When he married Judy Manning in 1963, he joined his brothers-in-law, Ken and Mike, as third-generation Brennan employees. That year, his father-in-law, Superintendent Joe Manning, hired him on permanently to help remove the Milwaukee Road Railroad Pontoon Bridge that crossed the river between Marquette, IA, and Prairie du Chien, WI. 2002 Little Guy in the 9270 at the The Milwaukee Road job introduced Ken to running a crane. As Kenny Lock and Dam 12 major rehab recalls, Even though he was Jim told me one day, “You look like a crane operator, give it a try,” and so often referred to as I did, and things turned out all right. Then at the end of the day, he come “Little Guy,” Ken Steiber up to me, and he said, “Now you’re a crane operator, and I’m giving you (Kenny) always had a a raise to 5 bucks an hour.” And man, that was big money! I went home big presence on the job that night and told my dad, and he said, “There ain’t nobody, but nobody, site. For a large portion of his career at Brennan, worth $5 an hour!” over 41 years, he was a foreman, superintendent, Kenny spent much of his career in the seat of a crane. He did everything certified crane operator, from pulling piling to placing rock to draglining. “Back then, if you couldn’t and licensed boat pilot. He stand the crane up on one track, you were a poor operator. To pull a piling, led from a unique position, you had to stand the crane up on one track and then drop it and catch it often directing crews and before the track would hit the barge. It would give a jerk, and then they’d running jobs from the seat come up.” of a crane or the pilothouse of a tugboat. When the Milwaukee Road job was complete, Kenny joined legendary employees like Leo McNally, George Kenyan, Paul Mitchell, Ralph Brennan, and his father-in-law to construct the I-90 Mississippi River Bridge over the Black River in La Crosse (still in use today). It was a big job where they mixed all their concrete on a barge salvaged from the Pontoon Bridge project. “My job was to keep the hoppers charged with sand and pea-gravel. Then I’d have to run into the bank, probably every other day or every so many days, and pick up a cement truck and bring out the cement and then blow it up into the hopper.” Later that year, Brennan built 1979 BN Rail Crane Salvage Wisconsin River-Kenny Steiber, our first office, located in Joe Manning, Jerry Bartheld, Ray Kronfrost, Cyril Mohn, what is now the parking lot of Roger Bean (Standing on Crane) our Safety Training Center. At the time, a big hole in that property needed to be filled. Luckily, we had a job just down the road from our yard for the Alter Metal Recycling

Company, where we were building 1981 Milwaukee Inner Harbor Mobilization-Lake Yeah, I can remember going down a dock next to the railroad bridge. Michigan Trip-Kenny Steiber (at helm) & John (Pinky) to Bellevue one time, and I went Kenny’s job was to run a dump into this one store to pick up truck carrying the excess material Proxman, Milwaukee Job something to eat for dinner. One from the dock project and dumping guy asked me what I was doing it into the hole. 1990s Ken Steiber on a spud barge (in town), and I told him I worked December 2000 - Lock and Dam 12 Major Rehab, for Brennan, and I’ll be putting on One story Kenny likes to tell rock as an operator. The guy then centered on an early interaction he Jeff Steiber, Bob Calvey, Neil Boser, Paul Tepp, responded, “So you’re that guy had with Jim Brennan, Cy Mohn, Rodger Bean, and Ken Steiber that could put on rock within a 6 IN tolerance?” You know all the locks Jim got to chewing me out for one 1997 Broke Arrow Slough Fleet Construction La Crosse that I put that rock on, I never had reason or another. I felt pretty bad to go over any of it. after that, so he came up to me and said, ‘Kenny, if you weren't Brennan remains forever grateful worthwhile chewing out, you for was Kenny’s commitment to the wouldn't be worthwhile having on company and his willingness to drop the job.’ For a long time, I thought everything when needed. “Brennans I was the most important man seemed to come before the family. Brennans had. I can still hear Jim If I was on holiday and they needed saying that. somebody to bail a barge, I was the one they called.” Thankfully he had In 1966, Kenny got his pilot’s strong support from his wife, Judy, license and began running tows when he accepted the call. Even in to various job sites. At the time, retirement, Kenny would drop ev- Brennan only had a few small erything when called upon for help. vessels. One of these, Jim He technically retired in 2003, but Brennan’s houseboat, the JA-DO, continued to help train young oper- had a set of tow-knees on the bow. ators, fill in as a crane operator or It was used as a workboat during pilot when needed, and even served the week and a family retreat on as a deckhand up until 2015. the weekends. Ken recalls, Kenny also left a significant impact on younger generations. As he I can remember a lot of times put it, coming up the river, just Jim and I, him smoking that cigar. God, I You know all the guys that got to be made a lot of trips up and down foremen worked for me at one time, the river with Jim. For some rea- and every one of them I would give son, Jerry Bartheld and I were the a bad time. Beany [Rodger Bean] only two that Jim would ever let could tell you a story. Jim O’Neill, take the JA-DO out. And they had Travis Schulte, Kevin Zenke all guys like Bud Calvey and all these could. Every one of them, I chewed other guys running boat. Nobody their butts out over something. But ever got to take the JA-DO out, but you know, every one of those guys either Jerry Bartheld or I, and for got to be a foreman. some reason, Jim always trusted me on that boat. I don’t know why. Ken was also proud of his talent as an operator and spoke fondly of During the 1970s, Brennan had a many of his crews. “At Brennans, few jobs along the Upper Mississippi, I could operate any piece of placing 300 LB stones at the toe of equipment. I did some welding, ran a dam to fix large scour areas that tugboats up and down the river. I formed on the downstream sides of worked with many different people. several lock and dam structures. On Seen a lot of change.” Changes those jobs, we had a tight placement at Brennan continue; however, tolerance to follow. We could place the Kenny’s impact on Brennan endures rock either 3 IN higher or 3 IN lower to because of his tremendous work the finished grade. Typically, there was ethic that influenced many who still a 3:1 slope, and the holes could be as work here, including his two sons, deep as 70 FT. Kenny developed quite Jeff and Jason Steiber. a reputation for his ability to place the stone within tolerance.

Thank you for your hardwork and dedication for the past 40 years Ringo!

Search

Read the Text Version

- 1 - 36

Pages: